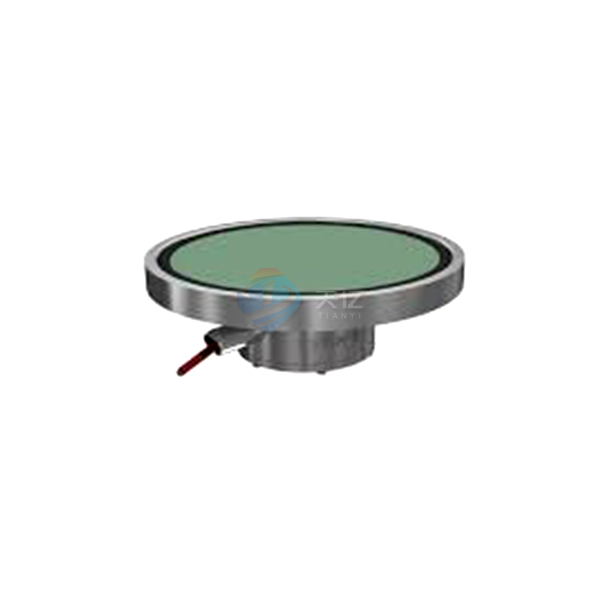

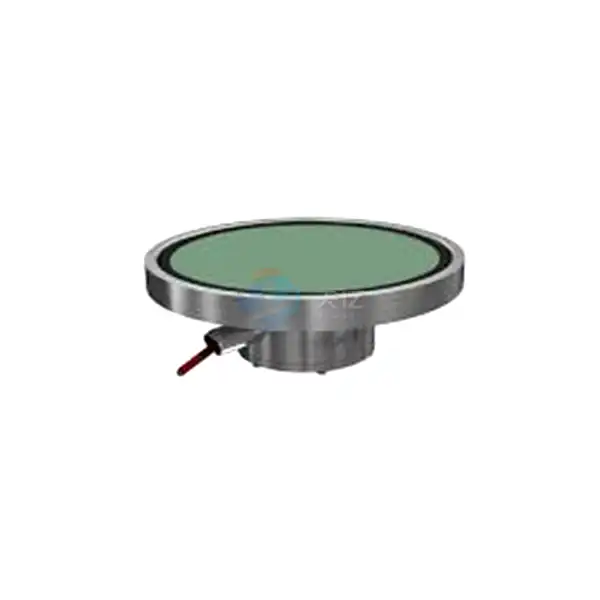

MMO Disc Anodes

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

MMO Disc Anodes Product Introduction

Welcome to our comprehensive overview of MMO Disc Anodes from Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. Our MMO (Mixed Metal Oxide) Disc Anodes are meticulously designed to provide superior performance in various electrochemical applications. These anodes play a crucial role in enhancing the efficiency and longevity of systems used in industries such as water treatment, electroplating, and cathodic protection. With advanced technology and robust materials, our anodes ensure reliable operation and optimal results.

Product Specifications

Substrate | Titanium Gr1 |

Coating | Iridium Oxide (IrO2), Ruthenium Oxide (RuO2), Tantalum Oxide (Ta2O5) |

Shape | Disc or Disk |

Diameter | φ25, φ60, φ100, φ150, |

Application | water tanks, Pressure Vessels, Oil and Gas Pipeline, Vessels |

Design Life | Specified 20-100 years |

Environment | Seawater environments/Marine Structures |

|  |

|  |

Product Composition and Design

Our MMO Disc Anodes are composed of high-purity titanium substrates, coated with a unique blend of ruthenium and iridium. This combination not only enhances the anodes' conductivity but also significantly improves their resistance to corrosion. The design is optimized for maximum surface area, ensuring efficient electrochemical reactions, making them ideal for both industrial and environmental applications.

Product Advantages

- High Durability: Our anodes are designed to withstand harsh environmental conditions, ensuring a long service life.

- Corrosion Resistance: The MMO coating provides excellent protection against corrosion, making them suitable for various applications.

- Enhanced Efficiency: The optimized design allows for superior performance in electrochemical processes, leading to reduced energy consumption.

- Customizable Options: We offer various sizes and coatings tailored to meet specific client requirements.

Technical Features

- Robust Construction: The titanium substrate ensures structural integrity, even in challenging environments.

- Superior Electrical Conductivity: The MMO coating maximizes current efficiency, reducing operational costs.

- Wide Application Range: Effective in multiple sectors, including mining, water treatment, and industrial electrolysis.

Product Application

MMO Disc Anodes are widely used across various industries, including:

Marine Structures: MMO disc anodes are widely used to protect marine structures such as ship hulls, docks, piers and offshore platforms. They counteract the corrosive effects of seawater on these structures.

Storage Tanks: They can be used on the bottom of above-ground storage tanks, on the outside of underground tanks to prevent corrosion.

Pipelines: MMO disc anodes are used to protect both onshore and offshore pipelines, ensuring they are protected from corrosion throughout their service life.

Water Treatment Facilities: They are also used in water treatment plants and desalination facilities to protect equipment from corrosive elements in the water.

Reinforced Concrete Structures: MMO disc anodes can be used to protect the steel reinforcement within concrete structures, preventing corrosion of the steel, thereby extending the service life of the structure.

Cooling Systems: In industrial cooling systems, MMO disc anodes can help protect infrastructure from the corrosive effects of coolants.

Electrochlorination Systems: They play a role in the production of chlorine from salt water, a process called electrochlorination.

Heat Exchangers: They can be used to protect heat exchangers from the corrosive effects of the fluids they handle.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process adheres to stringent quality control standards:

Material Selection

The production of MMO (Mixed Metal Oxide) disc anodes begins with selecting high-purity titanium substrates. The choice of titanium is due to its exceptional corrosion resistance and mechanical strength, which are critical for the longevity of the anodes in harsh electrochemical environments.

Disc Shaping

Titanium sheets are cut into the desired disc shape using precision cutting techniques such as laser cutting or water jet cutting. This process ensures that each disc meets specific diameter and thickness requirements, which are crucial for consistent performance.

Surface Preparation

The titanium discs undergo thorough surface preparation to enhance coating adhesion. This typically involves cleaning with acids or solvents to remove any contaminants, followed by mechanical treatments like sandblasting to create a roughened surface that improves the bonding of the MMO coating.

Coating Solution Preparation

A mixed metal oxide solution is formulated, often incorporating materials such as iridium oxide, ruthenium oxide, and tantalum oxide. These metal oxides are combined in precise ratios and dissolved in a suitable solvent to create a uniform coating solution.

Coating Application

The prepared MMO solution is applied to the surface of the titanium discs using methods like dip coating, spray coating, or electrochemical deposition. This step is critical for achieving a uniform and adherent coating that optimizes the anode's electrochemical activity.

Curing Process

After the coating is applied, the discs are subjected to a curing process, typically involving heating to facilitate the bonding of the MMO layer to the titanium substrate. Curing enhances the durability and effectiveness of the coating during operational use.

Quality Control Testing

Each batch of MMO disc anodes undergoes rigorous quality control testing. This includes measuring coating thickness, assessing adhesion strength, and evaluating electrochemical performance to ensure compliance with industry standards.

Final Inspection

After quality control, the disc anodes are subjected to a final inspection to verify dimensional accuracy, surface finish, and overall quality. This step ensures that only high-quality products proceed to packaging.

Packaging

The completed MMO disc anodes are carefully packaged to prevent damage during transport. Protective materials are used, and each package is labeled with essential information regarding the product specifications and handling instructions.

Documentation

Each shipment of MMO disc anodes includes documentation detailing product specifications, usage guidelines, and safety information. This ensures customers are well-informed for proper installation and operation.

Shipping

Finally, the packaged MMO disc anodes are shipped to customers using efficient logistics systems. Tracking mechanisms are in place to ensure timely delivery and customer satisfaction.

Through this meticulous production process, MMO disc anodes are manufactured to the highest standards, ensuring reliability and performance in various electrochemical applications, including wastewater treatment, chlorine production, and other industrial processes.

Quality Inspection

Quality is our priority. We implement comprehensive inspection protocols throughout the production lifecycle, ensuring:

- Consistency in product quality.

- Compliance with industry standards.

- Continuous improvement based on customer feedback.

Packaging Method

Our packaging solutions are designed for safety and efficiency:

- Protective Wrapping: Each anode is carefully wrapped to prevent damage during transit.

- Custom Packaging Options: We offer tailored packaging solutions to meet specific logistical requirements.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services that empower clients to customize anode specifications tailored to their unique needs. Our extensive range of options allows for adjustments in size, material, and design, ensuring that you receive products specifically suited to your application. Our flexibility and attention to detail guarantee that every solution we provide aligns with your operational requirements for optimal performance. Our experienced team collaborates closely with you throughout the process, from initial consultation to final production, ensuring a seamless experience. Trust Shaanxi Tianyi to deliver high-quality, customized anodes that enhance your product's efficiency and effectiveness.

FAQ

Q: What is the lifespan of products?

A: Our MMO Disc Anodes can last up to 10 years under optimal operating conditions.

Q: Are customization options available?

A: Yes, we offer a variety of sizes and coatings tailored to your specifications.

Q: What industries can benefit from your anodes?

A: Our anodes are suitable for water treatment, electroplating, cathodic protection, and hydrogen production.

Contact Us

For more information about our MMO Disc Anodes or to discuss your specific requirements, please contact us at info@di-nol.com. We are here to help you find the perfect solution for your electrochemical needs.

With our commitment to quality and innovation, Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. is your trusted partner in the field of electrochemical materials and technologies.

_1731573049210.webp)

_1731642350077.webp)