ICCP MMO Tubular Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

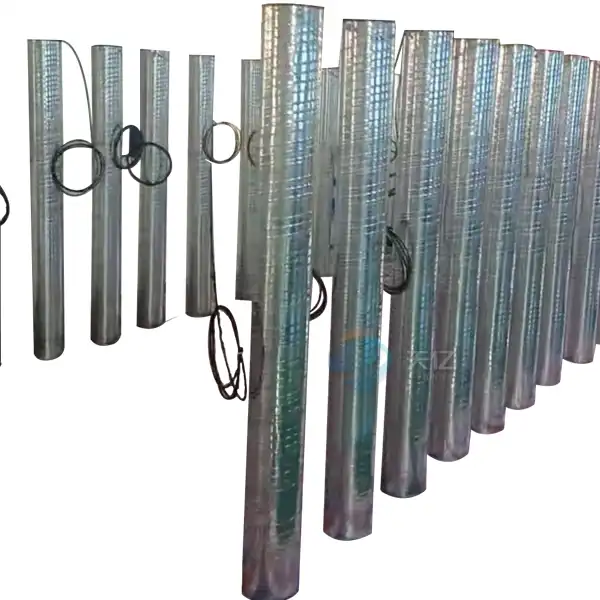

ICCP MMO Tubular Anode Introduction

An ICCP MMO tubular anode is a component of an impressed current cathodic protection (ICCP) system that's used to protect against corrosion:

What it is

An ICCP MMO tubular anode is a titanium anode coated with mixed metal oxide (MMO) that's connected to an external power source.

How it works

The power source provides the current that triggers an electrochemical reaction to protect against corrosion.

Product Show

Product Composition and Design

The ICCP MMO Tubular Anode is designed with a robust titanium substrate the coated with a carefully formulated mixture of ruthenium and iridium. This composition not only enhances the anode's electrical conductivity but also significantly improves its resistance to corrosion, making it ideal for long-term use in harsh environments.

Product Advantages

- Durability: Designed to withstand the extreme conditions, our anodes ensure long service life.

- Corrosion Resistance: The advanced coating materials provide exceptional protection against corrosion.

- Customizable: We offer various sizes and specifications tailored to meet your specific needs.

- High Efficiency: Optimized for maximum current density, ensuring effective performance in electrochemical processes.

Technical Features

- Advanced Coating Technology: Our proprietary coating the techniques enhance the performance of the MMO anodes.

- Robust Construction: Designed for structural integrity and reliability under operational stress.

- Eco-Friendly: Made with sustainable materials, contributing to environmental protection efforts.

Product Application

The ICCP MMO Tubular Anode is widely used in:

1. Marine industry

2. Oil and gas industry

3. Construction and infrastructure

4. Utilities and water treatment

5. Energy sector

6. Public infrastructure development

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process is optimized for the quality and consistency. We utilize:

Material Selection

The production of ICCP (Impressed Current Cathodic Protection) MMO (Mixed Metal Oxide) tubular anodes begins with selecting high-quality titanium as the substrate material. This choice is critical due to titanium's exceptional corrosion resistance, strength, and lightweight characteristics.

Design Specifications

The design phase involves creating detailed specifications for the tubular anodes. Engineers define the dimensions, wall thickness, and overall configuration to meet specific application requirements. This ensures that the anodes will fit properly within the intended cathodic protection systems.

Substrate Fabrication

Titanium tubes are fabricated through processes such as extrusion or tube rolling. The tubes are cut to the desired lengths and undergo various shaping processes to achieve the required curvature or profile. Precision is key during this step to ensure uniformity.

Surface Preparation

To enhance adhesion for the MMO coating, the titanium surfaces undergo thorough cleaning and preparation. Techniques like sandblasting or chemical etching are employed to create a roughened surface, increasing the bonding area for the subsequent coating application.

Application of MMO Coating

The MMO coating is applied using an electrochemical deposition technique. The prepared titanium tubular anodes are immersed in a coating bath containing mixed metal oxides, typically including iridium and tantalum. This process results in a uniform and durable coating that enhances the anode's performance.

Quality Inspection

Every ICCP MMO Tubular Anode undergoes rigorous quality control the checks, including:

- Material Inspection: Verifying the quality of raw materials.

- Coating Thickness Measurement: Ensuring adherence to specifications.

- Performance Testing: Confirming efficiency under operational conditions.

Packaging Method

Our anodes are packaged securely to prevent damage during the transit. We use:

- Custom Packaging Solutions: Tailored to the product dimensions for optimal protection.

- Eco-Friendly Materials: Contributing to sustainability while ensuring safety.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing you to customize the product to fit your unique specifications. From design to delivery, we collaborate closely with our partners to ensure satisfaction.We also focus on secure packing techniques. This includes layering items with protective material, filling void spaces to prevent shifting, and sealing packages securely to withstand the rigors of transportation.

FAQ

Q1: What is the typical lifespan of the product?

A1: Our anodes can last up to 20 years, depending on the application and environmental conditions.

Q2: Can you provide custom sizes for the anodes?

A2: Yes, we offer a range of sizes and can manufacture custom lengths to meet your needs.

Q3: What industries benefit from using these anodes?

A3: Industries such as water treatment, mining, and electroplating utilize our products.

Q4: How do I ensure I am using the correct anode for my application?

A4: Our technical team is available to assist in selecting the right anode for your specific application.

Contact Us

For more information about our ICCP MMO Tubular Anodes or to discuss your specific requirements, please reach out to us at [info@di-nol.com]. We're here to help you find the best solutions for your electrochemical needs!

YOU MAY LIKE

VIEW MOREplatinum coated titanium anode

VIEW MOREplatinum coated titanium anode VIEW MOREmmo coated titanium anodes for cathodic protection

VIEW MOREmmo coated titanium anodes for cathodic protection VIEW MOREiccp protected mmo coated titanium anodes

VIEW MOREiccp protected mmo coated titanium anodes VIEW MOREiccp mmo coated titanium anodes

VIEW MOREiccp mmo coated titanium anodes VIEW MOREPowered Water Heater Anode Rod

VIEW MOREPowered Water Heater Anode Rod VIEW MOREICCP MMO Ribbon Anodes

VIEW MOREICCP MMO Ribbon Anodes VIEW MOREICCP MMO Canister Anode

VIEW MOREICCP MMO Canister Anode VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil

VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil

_1731573049210.webp)