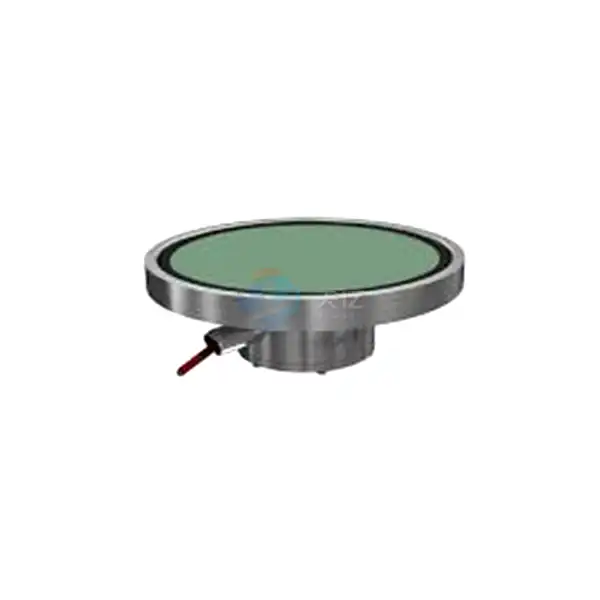

MMO Disk Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

MMO Disk Anode Product Introduction

Welcome to the future of electrochemical technology with our MMO Disk Anode! At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we pride ourselves on offering top-tier Mixed Metal Oxide (MMO) coated titanium anodes that are integral to various industries, including water treatment, electroplating, and cathodic protection. Our products are designed to enhance efficiency and durability in your electrochemical processes, ensuring you achieve the highest performance standards.

Product Specifications

Substrate | Titanium Gr1 |

Coating | Iridium Oxide (IrO2), Ruthenium Oxide (RuO2), Tantalum Oxide (Ta2O5) |

Shape | Disc or Disk |

Diameter | φ25, φ60, φ100, φ150, |

Application | water tanks, Pressure Vessels, Oil and Gas Pipeline, Vessels |

Design Life | Specified 20-100 years |

Environment | Seawater environments/Marine Structures |

|  |

|  |

Product Composition and Design

The MMO Disk Anode is constructed from high-quality titanium alloy, ensuring superior corrosion resistance and durability. The anodes are coated with a proprietary blend of mixed metal oxides, enhancing their electrochemical performance and allowing for optimal operation in diverse environments. Our design also accommodates various sizes and configurations to meet specific application requirements.

Product Advantages

- Long Lifespan: Our products are engineered for extended durability, reducing the need for frequent replacements.

- High Efficiency: The advanced coating technology ensures optimal electron transfer, maximizing performance in electrochemical applications.

- Customizable Options: We offer a range of sizes and specifications tailored to your unique operational needs.

Technical Features

- Corrosion Resistance: The titanium substrate provides excellent resistance to corrosion, making it suitable for harsh environments.

- Stable Performance: Designed to maintain consistent performance across various operating conditions.

- High Current Density: Capable of supporting high current densities, ideal for demanding applications.

Product Application

The MMO Disk Anode is widely used in:

Marine Structures: MMO disc anodes are widely used to protect marine structures such as ship hulls, docks, piers and offshore platforms. They counteract the corrosive effects of seawater on these structures.

Storage Tanks: They can be used on the bottom of above-ground storage tanks, on the outside of underground tanks to prevent corrosion.

Pipelines: MMO disc anodes are used to protect both onshore and offshore pipelines, ensuring they are protected from corrosion throughout their service life.

Water Treatment Facilities: They are also used in water treatment plants and desalination facilities to protect equipment from corrosive elements in the water.

Reinforced Concrete Structures: MMO disc anodes can be used to protect the steel reinforcement within concrete structures, preventing corrosion of the steel, thereby extending the service life of the structure.

Cooling Systems: In industrial cooling systems, MMO disc anodes can help protect infrastructure from the corrosive effects of coolants.

Electrochlorination Systems: They play a role in the production of chlorine from salt water, a process called electrochlorination.

Heat Exchangers: They can be used to protect heat exchangers from the corrosive effects of the fluids they handle.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Raw Material Selection

The production of MMO (Mixed Metal Oxide) disk anodes begins with the selection of high-quality titanium as the substrate material. Titanium is chosen for its excellent corrosion resistance and mechanical properties, making it ideal for use in electrochemical applications.

Disc Shaping

Titanium sheets are cut into disk shapes using precision methods like laser cutting or water jet cutting. This ensures that each disk meets the required specifications for diameter and thickness, which are essential for optimal performance.

Surface Treatment

The titanium disks undergo surface preparation to enhance coating adhesion. This typically involves cleaning with acidic solutions or solvents to remove any surface contaminants, followed by mechanical abrasion, such as sandblasting, to create a roughened surface for better bonding of the MMO coating.

Coating Preparation

A mixed metal oxide coating solution is formulated, typically including iridium oxide, ruthenium oxide, and tantalum oxide. The oxides are mixed in precise proportions and dissolved in a suitable solvent, creating a uniform coating solution.

Coating Application

The prepared MMO solution is applied to the titanium disks using methods such as dip coating, spray coating, or electrochemical deposition. This step is crucial for achieving a consistent and adherent coating that enhances the anode’s electrochemical activity.

Curing Process

After coating, the disks are subjected to a curing process, usually involving heating to promote the bonding of the MMO layer to the titanium substrate. Curing enhances the durability and electrochemical performance of the coating.

Quality Control

Each batch of MMO disk anodes undergoes rigorous quality control testing. This includes measuring coating thickness, checking adhesion strength, and evaluating electrochemical performance to ensure compliance with industry standards.

Final Inspection

The disk anodes are subjected to a final inspection to verify dimensional accuracy, surface finish, and overall quality. This step ensures that only high-quality products are packaged and shipped.

Packaging

The completed MMO disk anodes are carefully packaged using protective materials to prevent damage during transportation. Each package is labeled with essential product specifications and handling instructions.

Documentation

Accompanying each shipment of MMO disk anodes is documentation that outlines product specifications, usage guidelines, and safety information, ensuring customers are fully informed for proper installation and operation.

Shipping

Finally, the packaged MMO disk anodes are shipped to customers using reliable logistics systems. Tracking mechanisms are in place to ensure timely delivery and customer satisfaction.

By following this meticulous production process, MMO disk anodes are manufactured to the highest standards, ensuring reliability and efficiency in various electrochemical applications, including water treatment, chlorine production, and other industrial uses.

Quality Inspection

At Shaanxi Tianyi, we prioritize quality. Our inspection process includes:

- Raw Material Checks: Ensuring only the highest quality titanium and metal oxides are used.

- In-Process Monitoring: Continuous checks throughout the manufacturing process to maintain standards.

- Final Testing: Comprehensive testing to guarantee that every product meets or exceeds industry benchmarks.

Packaging Method

We utilize custom packaging solutions designed to ensure the safety and integrity of the MMO Disk Anodes during transit. Our packaging methods are cost-effective and environmentally friendly, designed to meet international shipping standards.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We are pleased to offer OEM services for our products, providing tailor-made solutions that align with your specific requirements. Whether you need customized coatings or unique specifications, our team is ready to assist you.

FAQ

Q: What is an product?

A: An product is a titanium anode coated with mixed metal oxides, designed for high-performance electrochemical applications.

Q: How do I determine the right size for my application?

A: We offer customizable sizes to meet specific operational requirements. Please contact us for guidance on selecting the appropriate dimensions.

Q: What industries use these?

A: These anodes are widely used in water treatment, electroplating, and cathodic protection, among others.

Q: How long can I expect the anode to last?

A: The lifespan of an product depends on various factors, including operating conditions and maintenance. However, they are engineered for extended durability.

Contact Us

For more information about our MMO Disk Anodes or to place an order, please contact us at info@di-nol.com. Our dedicated team is here to assist you with your electrochemical material needs!

_1731573049210.webp)