electrolytic sodium hypochlorite generator

Corrosion resistance

Tailored precision, customizable in size, dimensions and capacity

Integrated titanium welding and flange technology effectively prevents high pressure buildup and ensures strong welds

Ruthenium and iridium oxide nano-coating Coating can extend the service life of the electrolyzer to five years

- Product Description

Electrolytic Sodium Hypochlorite Generator Introduction

Our Electrolytic Sodium Hypochlorite Generator offers a cutting-edge solution for generating sodium hypochlorite on-site, ensuring safe and efficient water treatment. Ideal for various industries, including water purification, swimming pool maintenance, and food processing, this generator is designed to meet your disinfection needs with minimal environmental impact.

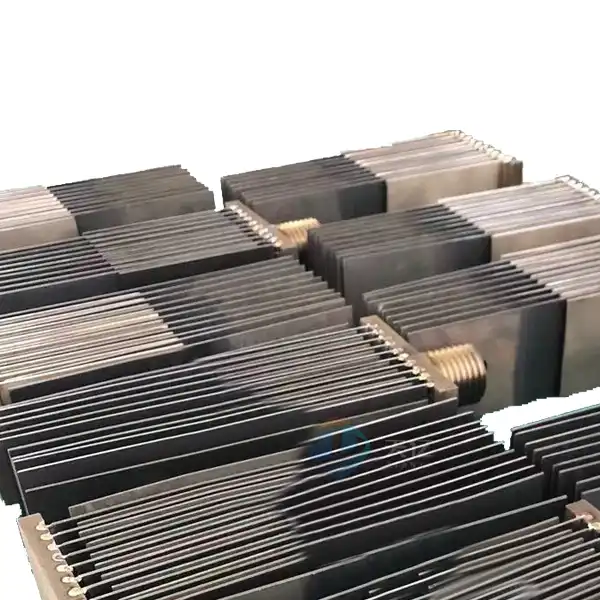

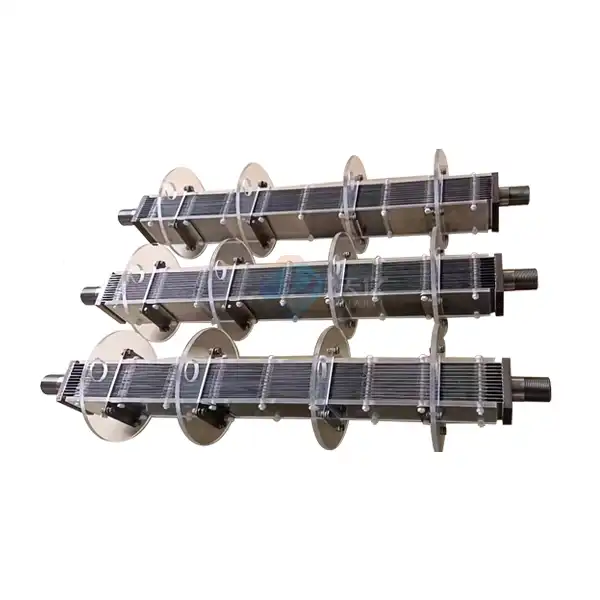

Product Show

| Effective chlorine output | Available chlorine concentration | Design flow | Service life | Shell material |

| 30-50g/h | 2000-8000ppm | 7L/h----8L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 100g/h | 2000-8000ppm | 20L/h----25L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 200g/h | 2000-8000ppm | 1-2Year,2-3Year,3-5Year5-8Over 10 years | PMMA/UPVC | |

| 300g/h | 2000-8000ppm | 30L/h----35L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 500g/h | 2000-8000ppm | 75L/h----85L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 1000g/h | 2000-8000ppm | 105L/h----110L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 2000g/h | 2000-8000ppm | 135L/h----145L/h | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

| 3000g/h | 2000-8000ppm | 1-2Year,2-3Year,3-5Year5Over 10 years | PMMA/UPVC |

|  |  |

|  |  |

Product Composition and Design

Our electrolytic sodium hypochlorite generator is built with high-quality materials designed for durability and efficiency. The core components include:

Electrolytic Cell: Made from titanium and coated with MMO, ensuring long life and effective chlorine production.

Control Unit: An intuitive touchscreen interface for easy operation and monitoring.

Reactor Chamber: Designed for optimal mixing of saltwater and electricity to produce sodium hypochlorite efficiently.

Product Advantages

On-Site Production: Generate sodium hypochlorite on-site, reducing transportation and storage costs.

Eco-Friendly: Utilizes salt and water, minimizing the environmental impact compared to traditional chemical methods.

Cost-Effective: Reduces reliance on commercial disinfectants, saving you money over time.

User-Friendly: The touchscreen interface makes operation straightforward, even for non-technical personnel.

Technical Features

High Efficiency: Capable of producing high concentrations of sodium hypochlorite quickly and effectively.

Robust Design: Built to withstand harsh environments, ensuring longevity and reliability.

Safety Mechanisms: Includes alarms and automatic shutdown features to enhance user safety.

Product Application

Our electrolytic sodium hypochlorite generator is versatile and can be used in various applications, including:

1. Industrial Cooling Water Treatment

2.Marine and Cruise Water Disinfection

3.Rural Water Treatment Solutions

4.Urban Water Treatment Solutions

5.Wastewater Treatment Solutions

6.Food and Beverage Safety through Disinfection

7.Pool Water Disinfection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process emphasizes quality and precision:

Material Selection

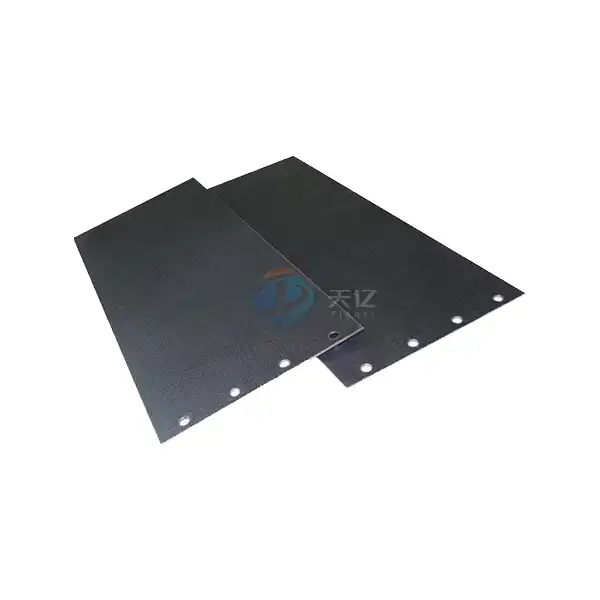

Corrosion-resistant materials, such as titanium or coated electrodes, are chosen for durability under the generator's saline and electrolytic environment. Additional cell components use compatible alloys to withstand continuous operation.

Engineering and Design

The sodium hypochlorite generator is designed to maximize production efficiency. Engineering focuses on electrode layout, optimal spacing, and flow dynamics to ensure efficient electrolysis and consistent sodium hypochlorite output.

Electrode Cutting and Shaping

Titanium sheets or rods are cut and formed based on detailed design specifications using laser cutting and CNC machining. This ensures dimensional accuracy for precise assembly within the cell.

Surface Treatment of Electrodes

The electrodes undergo surface treatments, such as sandblasting or acid etching, to improve coating adhesion. A treated surface ensures that applied coatings bond strongly, extending electrode lifespan.

Coating Application

Electrodes are coated with mixed metal oxides (MMO) or platinum group metals to enhance conductivity and corrosion resistance. The coating process uses techniques like thermal spraying or electrochemical deposition to ensure a uniform application.

Cell Assembly

Coated electrodes and other cell components are assembled with precise spacing for effective brine solution flow. The electrodes are aligned to optimize electric current distribution and hypochlorite production.

Brine Solution Preparation

Sodium chloride (NaCl) is dissolved in water to prepare the brine solution, which acts as the electrolyte. This solution is essential for generating sodium hypochlorite when subjected to electrolysis.

Quality Inspection

Quality is our priority. We conduct comprehensive inspections throughout the production process, including:

Raw material checks

In-process evaluations

Final performance testing to ensure compliance with industry standards

Packaging Method

Our electrolytic sodium hypochlorite generators are securely packaged using:

Custom Foam Inserts: To prevent damage during transit.

Moisture-Proof Wrapping: Ensuring the product remains dry and intact.

Labeling: Clearly marked for easy identification and handling.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer customized solutions tailored to your specific requirements. Whether you need different output capacities or unique design features, our team is ready to help you find the perfect solution for your needs.

FAQ

Q: How does the generator work?

A: The generator electrolyzes a saltwater solution, producing sodium hypochlorite on-site.

Q: What maintenance is required?

A: Regular cleaning of the electrolytic cell and periodic inspection of components ensure optimal performance.

Q: Can the generator be used for large-scale applications?

A: Yes, we offer models with varying output capacities to suit different operational needs.

Q: Is training available for operators?

A: Absolutely! We provide training sessions to ensure your team is confident in operating the generator.

Contact Us

Prepared to improve your water treatment process? Get in touch with us today for additional data about our Electrolytic Sodium Hypochlorite Generator and how it can help your tasks. Our high level generator is intended to create great sodium hypochlorite on location, giving a practical and proficient answer for water sanitization. Go ahead and out by means of email at info@di-nol.com; we anticipate assisting you with accomplishing ideal water quality!

YOU MAY LIKE

_1731641984159.webp) VIEW MOREDiaphragmless electrolyzer

VIEW MOREDiaphragmless electrolyzer VIEW MOREIr-Ta oxide coated DSA electrode

VIEW MOREIr-Ta oxide coated DSA electrode_1731642034207.webp) VIEW MORESodium hypochlorite electrolytic cell

VIEW MORESodium hypochlorite electrolytic cell VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode_1731642084407.webp) VIEW MOREchlorine electrolyzer

VIEW MOREchlorine electrolyzer_1731642120915.webp) VIEW MOREchlor alkali electrolyzer

VIEW MOREchlor alkali electrolyzer_1731642168251.webp) VIEW MOREtitanium electrolyzer for electro-chlorination

VIEW MOREtitanium electrolyzer for electro-chlorination