MMO Ribbon Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd.! We proudly present our MMO Ribbon Anode, a high-performance electrochemical solution designed for a wide range of industrial applications. Made from advanced materials, our products are engineered to provide exceptional durability, corrosion resistance, and efficiency in electrochemical processes. Whether you are involved in water treatment, electroplating, or cathodic protection, our anodes deliver reliable performance and outstanding results.

Product Specifications

| Coating | Titanium substrate | Specification | Standard length | Design life |

| Iridium-tantalum/ruthenium-iridium mixed oxide | GR1/GR2 | 6.35mm × thickness 0.635mm | 152 meters/roll | 20 to 50 years |

| (MMO coating) | 12.7mm × thickness 0.9mm | or 150 meters/roll |

|  |  |

|  |  |

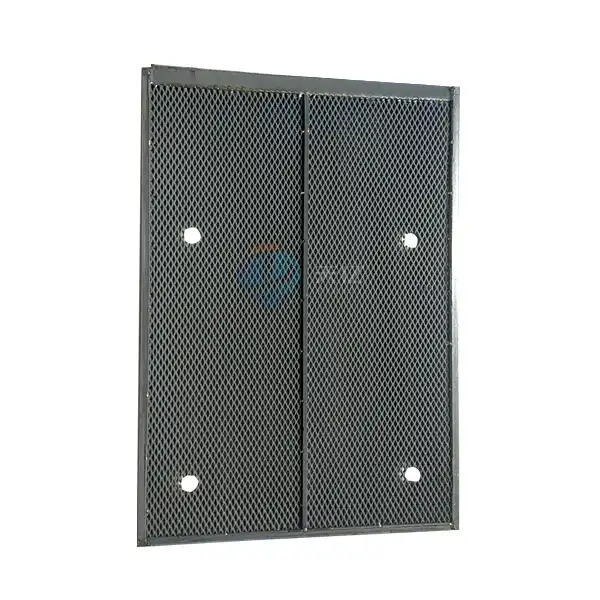

Product Composition and Design

Our MMO Ribbon Anodes feature a unique design that maximizes surface area while minimizing resistance. The titanium substrate is coated with a mixed metal oxide layer, typically consisting of ruthenium and iridium. This composition ensures high electrical conductivity and superior resistance to corrosion, making our anodes suitable for demanding environments.

Product Advantages

High Efficiency: Designed to deliver excellent electrochemical performance.

Long Service Life: Built to withstand harsh conditions, ensuring extended durability.

Customizable: Available in various sizes and configurations to meet specific application needs.

Eco-Friendly: Contributes to sustainable practices in electrochemical applications.

Technical Features

Our MMO Ribbon Anodes incorporate advanced technology for optimal performance. Key features include:

Enhanced Current Distribution: Promotes uniform current flow, reducing hotspots and increasing anode lifespan.

Corrosion Resistance: The MMO coating protects the titanium base from aggressive environments.

Versatile Applications: Suitable for various industries, including water treatment, mining, and electroplating.

Product Application

The product is ideal for:

1.Pipeline inner wall corrosion protection

2.Underground storage tanks, ground storage tanks, water storage tanks

3.Condensate tanks, heat exchangers, water treatment equipment

4.Ships, roads, bridges, building steel corrosion protection, etc.

5.Continuous horizontal ground bed, non-continuous horizontal ground bed, shallow buried vertical ground bed.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process for MMO Ribbon Anodes is meticulously controlled to ensure the highest quality. Key stages include:

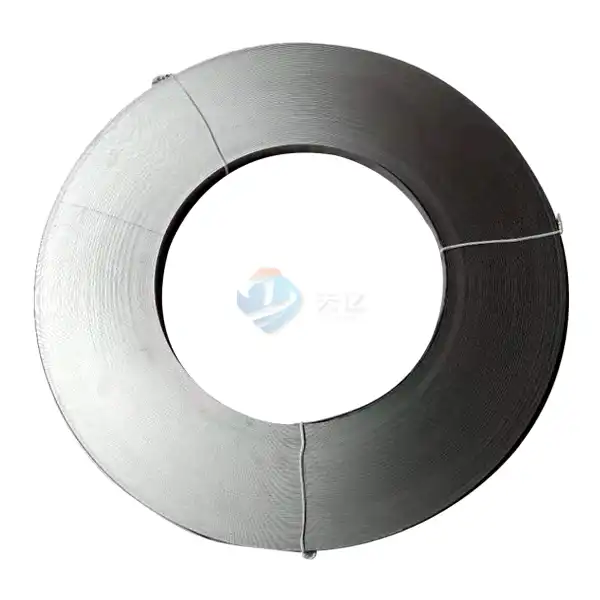

Titanium Ribbon Selection

Premium titanium ribbons are selected for their durability and corrosion resistance, particularly in aggressive environments. Each ribbon is inspected for quality and consistency to ensure long-term performance in cathodic protection applications.

Surface Preparation

The ribbons undergo surface treatment, including acid washing or abrasive cleaning, to remove contaminants. This process roughens the surface to improve the adhesion of the MMO (Mixed Metal Oxide) coating.

Mixed Metal Oxide Coating Application

A specialized MMO coating, often containing elements like iridium or ruthenium, is applied to the ribbons. This coating is typically applied through dip-coating or spraying methods, followed by high-temperature curing to bond the oxide to the titanium substrate effectively.

Quality Control of Coating

The coated ribbons are tested for coating thickness, uniformity, and adhesion. Electrical conductivity and durability tests are also conducted to ensure the anode will perform consistently in the field.

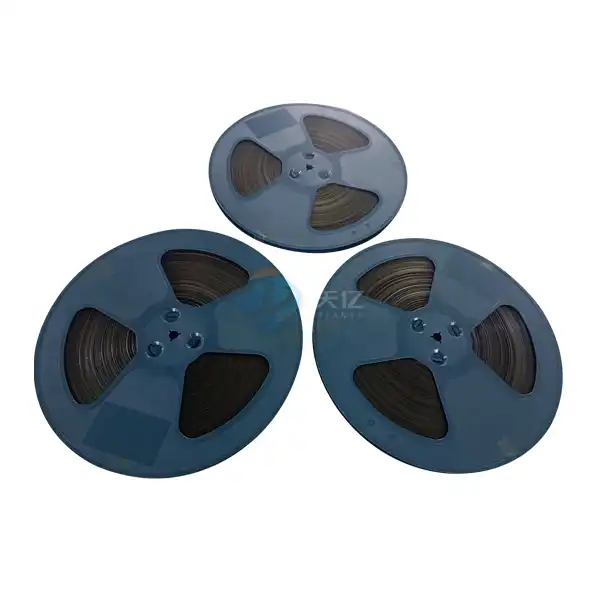

Cutting to Length

The MMO-coated ribbons are cut to specified lengths based on customer requirements. Custom lengths enable precise installations in various cathodic protection systems, particularly in concrete or soil environments.

Connection Preparation

High-quality, corrosion-resistant connectors are attached to each anode for optimal electrical conductivity. Connection points are insulated to minimize current loss and ensure effective performance over time.

Final Inspection

Each MMO ribbon anode undergoes a final inspection to check for any defects in coating, surface irregularities, or inconsistencies. Mechanical and electrical tests confirm that each anode meets the specified requirements.

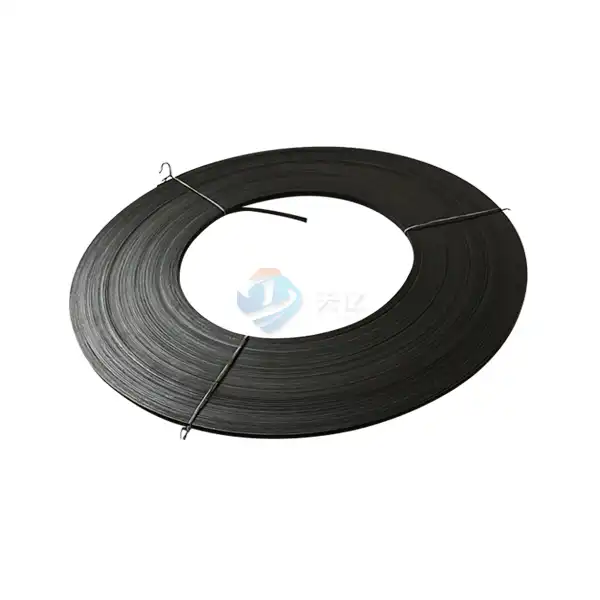

Packaging and Documentation

The finished ribbon anodes are carefully packaged to avoid bending or surface damage. Installation and operational guidelines are provided along with technical specifications to facilitate efficient and correct installation in cathodic protection systems.

Quality Inspection

We adhere to strict quality control protocols. Each product undergoes comprehensive testing to verify:

Coating Integrity: Ensures uniform application and adherence.

Performance Metrics: Confirms efficiency and durability under various conditions.

Packaging Method

Our packaging solutions are designed to protect the anodes during transit. We utilize:

Custom Packaging: Tailored to the product dimensions to prevent damage.

Environmentally Friendly Materials: Ensures sustainability while providing protection.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing you to customize your products to meet specific requirements. We work closely with our partners to deliver tailored solutions that enhance performance and align with unique operational needs.

FAQ

Q1: What industries can benefit from the product?

A: Industries such as water treatment, mining, electroplating, and cathodic protection can greatly benefit from our anodes.

Q2: How long do it last?

A: Our anodes typically have a service life of 5-10 years, depending on the application and operating conditions.

Q3: Can I order custom sizes?

A: Yes, we offer customizable solutions to meet your specific needs.

Q4: What is the lead time for orders?

A: Lead times vary based on order specifications but generally range from 4 to 6 weeks.

Contact Us

For more data about our MMO Ribbon Anodes or to talk about your necessities, go ahead and connect with us at info@di-nol.com. At Shaanxi Tianyi New Material Titanium Anode Innovation Co., Ltd., we are focused on giving remarkable items and backing. Our group of specialists is devoted to figuring out your particular necessities and conveying custom fitted arrangements that improve your electrochemical applications. We offer an extensive variety of top notch titanium anodes, including different designs and coatings, to suit different ventures. By picking us as your accomplice, you get to imaginative advances and solid client support that guarantees your ventures succeed. Go ahead and us today — let us assist you with accomplishing your objectives in electrochemical advances!

_1731642393023.webp)