Canister Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

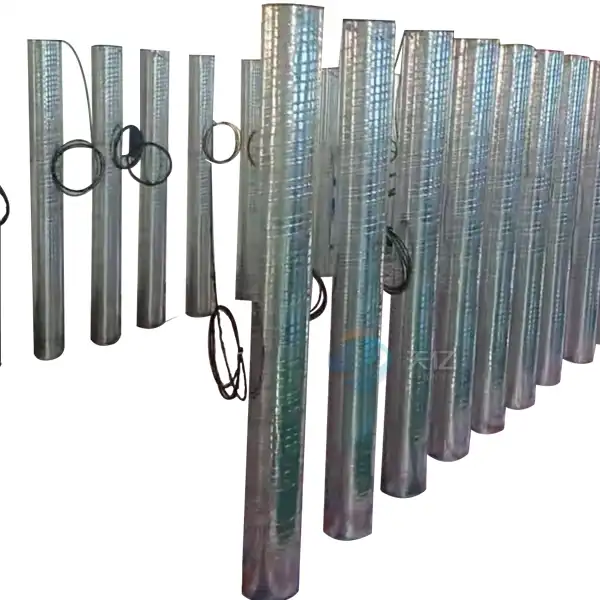

Canister Anode Introduction

At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd, we specialize in advanced electrochemical electrode materials, including our high-performance Canister Anode. Designed for various industrial applications, these anodes are crafted from durable, corrosion-resistant materials to ensure optimal performance in demanding environments. Whether you’re involved in water treatment, electroplating, or hydrogen production, our products are engineered to meet your specific needs.

Product Specifications

Cylinder length (mm) | Cylinder outer diameter (mm) | Anode length (mm) | Cable Type |

1000 | 80 | 800 | PVDF/HMWPE |

1500 | 100 | 1200 | PVDF/HMWPE |

2000 | 150 | 1800 | PVDF/HMWPE |

|  |

|  |

Product Composition and Design

Our Canister Anodes feature a robust construction that includes a specialized coating of Ruthenium-Iridium, known for its excellent electrochemical performance and durability. The canister design ensures a uniform distribution of current, optimizing the anode's efficiency while minimizing the risk of localized corrosion. This design is ideal for applications requiring high reliability and performance.

Product Advantages

- High Performance: Our products provide superior electrochemical activity, enhancing operational efficiency.

- Corrosion Resistance: Built to withstand harsh environments, ensuring longevity and reduced maintenance.

- Customizable Sizes: Tailored to fit your specific project requirements, promoting versatility in application.

- Cost-Effective: Designed for long service life, reducing the need for frequent replacements and saving costs.

Technical Features

- Electrochemical Efficiency: High current density capability for faster processing times.

- Temperature Stability: Effective operation in high-temperature environments without compromising performance.

- Flexibility in Use: Suitable for various electrochemical applications, from water treatment to industrial electroplating.

Canister Anode Application

Our Canister Anode is widely used across various industries, including:

MMO cylindrical anode application areas:

1. Cathodic protection of industrial and urban underground pipelines;

2. Cathodic protection of metal pipeline structures;

3. Cathodic protection of deeply buried and underwater metal components;

4. Protected bodies at depths that cannot be reached by other cathodic protection methods.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

At Shaanxi Tianyi, we follow a rigorous production process that includes:

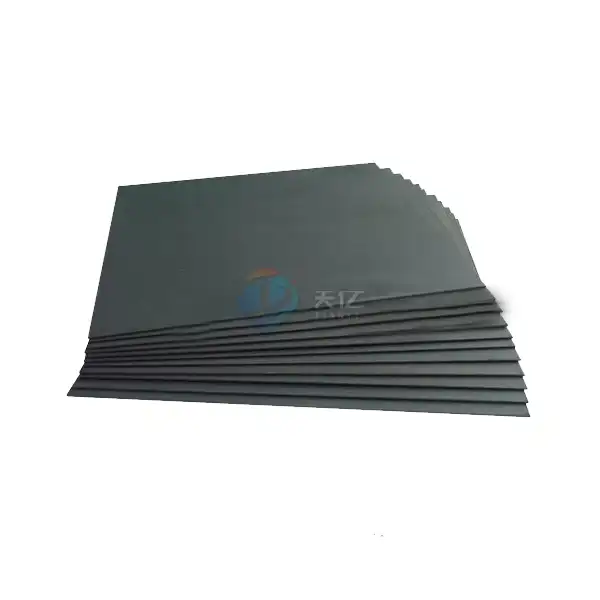

Material Selection

The production of canister anodes begins with selecting high-quality materials, typically titanium or other corrosion-resistant alloys. These materials are chosen for their durability and electrochemical performance, which are essential for effective cathodic protection in various applications, including water storage tanks and pipelines.

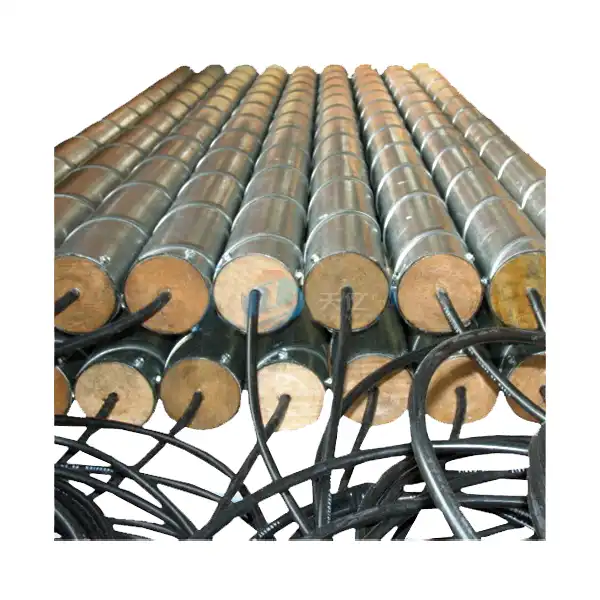

Canister Fabrication

The selected metal is formed into cylindrical canisters. This can involve processes such as rolling and welding, where sheets of titanium are shaped and joined to create a hollow structure. The canisters are designed to be robust and to provide sufficient space for the electrolyte and anode materials.

Surface Preparation

To ensure proper adhesion of the anode coating, the canisters undergo surface preparation. This typically includes cleaning processes, such as acid pickling, to remove surface oxides and contaminants. A roughened surface may also be achieved through sandblasting or abrasive techniques to enhance coating adhesion.

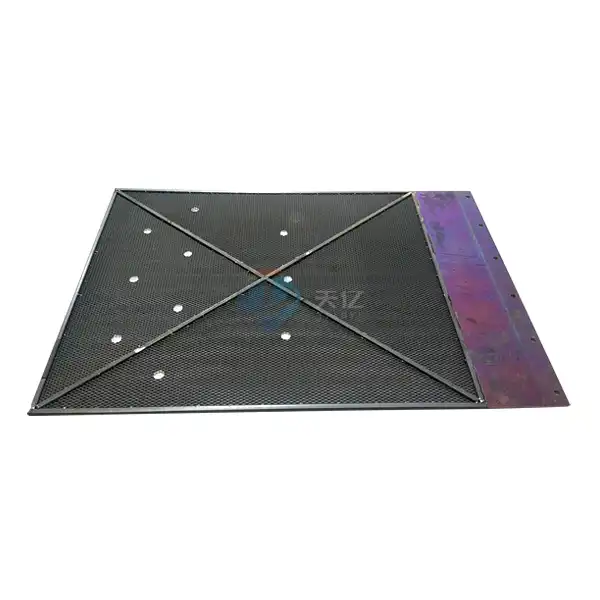

Coating Application

The canisters are then coated with a protective layer of mixed metal oxides (MMO) or other suitable coatings. This is often accomplished using an electrochemical deposition method, where the canisters are submerged in a solution containing metal oxides. An electrical current is applied, facilitating the deposition of the oxide layer onto the canister surfaces.

Quality Inspection

Our commitment to quality is reflected in our thorough inspection processes, which include:

- Material Testing: Ensuring raw materials meet specified standards.

- In-Process Checks: Continuous monitoring during production to maintain quality.

- Final Product Evaluation: Comprehensive testing to confirm that all products exceed performance benchmarks.

Packaging Method

Our Canister Anodes are packaged securely to ensure safe transportation. We use eco-friendly materials that protect the products from damage while minimizing environmental impact. Custom packaging solutions are available based on client requirements.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We provide extensive OEM services designed to meet your unique specifications and requirements. Whether you need custom sizes, specialized coatings, or specific configurations, our dedicated team is here to deliver tailored solutions that align with your operational needs. We take pride in our collaborative approach, working closely with you throughout the design and production process to ensure that every detail is meticulously addressed. Our commitment to quality and performance guarantees that the final products not only meet but exceed your expectations. Trust us to help you bring your vision to life with precision and expertise.

FAQ

Q: What is the lifespan of a product?

A: Our products are designed for over 5 years of service life, depending on the operating conditions.

Q: Can I customize the size of the products?

A: Yes, we offer customizable sizes to fit your specific application requirements.

Q: What industries use these?

A: Our products are utilized in water treatment, electroplating, hydrogen production, and more.

Contact Us

For more information about our Canister Anode or to discuss your specific needs, please reach out to us at info@di-nol.com. We look forward to partnering with you and providing solutions that enhance your operational efficiency!

YOU MAY LIKE

VIEW MOREmmo coated titanium anodes for cathodic protection

VIEW MOREmmo coated titanium anodes for cathodic protection VIEW MORELead oxide electrode

VIEW MORELead oxide electrode VIEW MORELead dioxide anode

VIEW MORELead dioxide anode VIEW MOREWater heater power anode rod

VIEW MOREWater heater power anode rod VIEW MOREelectrolysis titanium electrode

VIEW MOREelectrolysis titanium electrode VIEW MOREtitanium alloy electrodes

VIEW MOREtitanium alloy electrodes VIEW MOREMMO titanium anode for electrolytic chlorine production equipment

VIEW MOREMMO titanium anode for electrolytic chlorine production equipment

_1731223005159.webp)