MMO titanium anode for electrolytic chlorine production equipment

Uniform current distribution

High electrolysis efficiency

Reduced power consumption

Long service life

- Product Description

Product Introduction

Welcome to the world of advanced electrochemical technologies! Our MMO Titanium Anode for Electrolytic Chlorine Production Equipment is meticulously engineered to meet the rigorous demands of various industrial applications. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we take great pride in producing high-performance MMO-coated titanium anodes, which are essential for facilitating efficient chlorine production through electrolysis. Our innovative anodes are designed not only to optimize the electrochemical process but also to ensure longevity and reliability in challenging operational environments, making them a vital component for businesses seeking to enhance their production capabilities. With our commitment to quality and innovation, we empower our clients to achieve superior results in their electrolysis processes.

Product Specifications

| Parameter | Details |

|---|---|

| Base Material | Titanium (Grade 1 or Grade 2) |

| Coating Material | Mixed Metal Oxide (MMO) |

| Current Density | 500-2000 A/m² |

| Operating Temperature | Up to 60°C |

| pH Range | 1 - 12 |

| Lifespan | 3 - 5 years, depending on operating conditions |

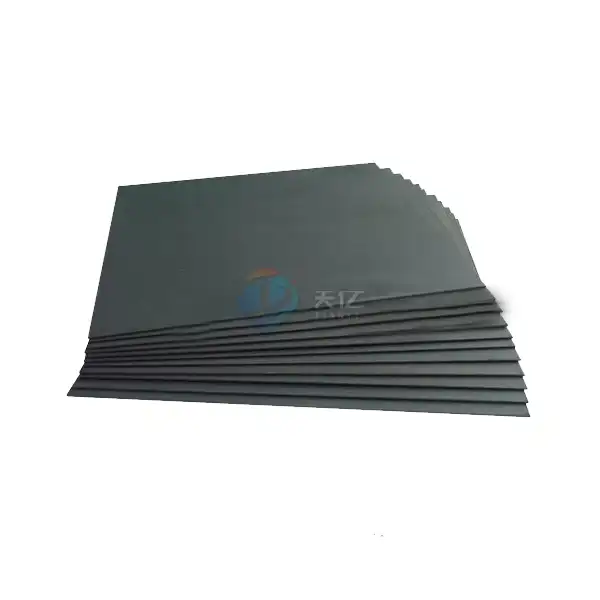

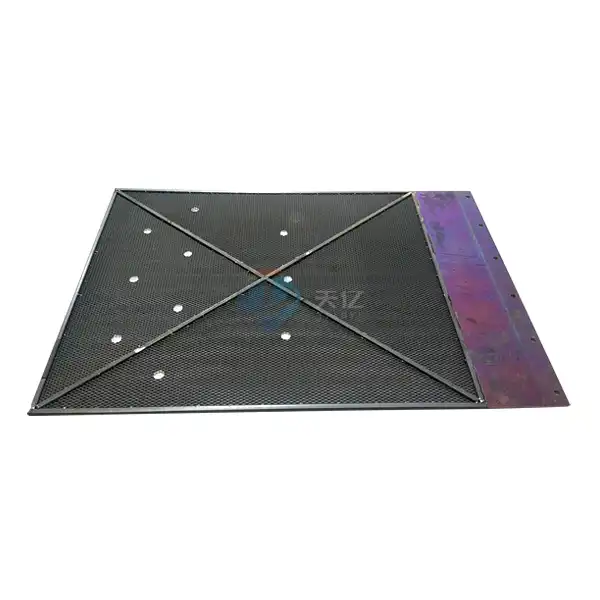

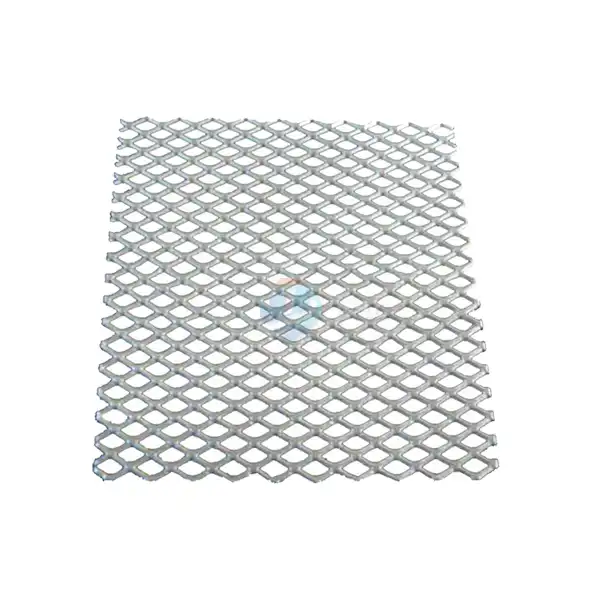

| Electrode Shape | Plate, rod, tube, mesh |

| Coating Thickness | 5 - 20 µm |

| Voltage | 4.0 - 5.5 V |

| Applications | Chlor-alkali industry, seawater electrolysis |

| Dimensions | Customizable according to equipment requirements |

| Certifications | ISO 9001, CE |

|  |  |

Product Composition and Design

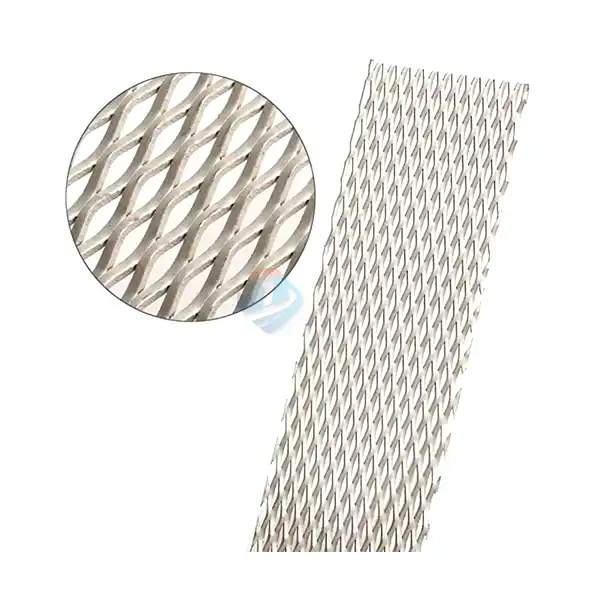

OurMMO Titanium Anode for Electrolytic Chlorine Production Equipment are expertly crafted using high-purity titanium substrates, which are then coated with a specialized mixed metal oxide layer. This innovative design guarantees high conductivity and superior performance, facilitating efficient chlorine production. Moreover, the choice of coatings can be tailored to meet specific application needs, allowing us to enhance the anode's performance based on the unique requirements of each client's operational environment. This level of customization ensures optimal results and increased efficiency for various industrial applications.

Product Advantages

- Durability: Our anodes are designed to withstand harsh electrochemical environments, ensuring long service life.

- High Efficiency: The advanced coating technology maximizes current efficiency, reducing energy costs.

- Customizable Solutions: We offer various sizes and coating types to suit your specific needs.

- Eco-Friendly: Our products support sustainable practices in chlorine production, aligning with environmental compliance standards.

Technical Features

- Corrosion Resistance: Our anodes resist corrosion, minimizing maintenance needs.

- Temperature Stability: They perform optimally under varying temperature conditions.

- High Current Density: Capable of operating at higher current densities without loss of performance.

Product Application

The MMO Titanium Anode for Electrolytic Chlorine Production Equipment is widely used in:

- Water Treatment: For disinfecting and purifying water supplies.

- Electroplating: Enhancing surface coatings on various substrates.

- Chemical Manufacturing: Producing chlorine for industrial processes.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process is meticulous, involving:

Material Selection

Utilize high-grade titanium, typically Grade 2, for its excellent corrosion resistance and mechanical strength, particularly in chlorinated environments. The choice of titanium is crucial to enhance the anode's durability and efficiency.

Design Specifications

Determine the anode design based on operational requirements, including dimensions, shape, and surface area. The design must optimize the electrochemical reactions for chlorine production while ensuring structural integrity.

Forming the Anode

Employ techniques such as machining, forging, or rolling to shape the titanium into the specified anode form. Precision in this step is vital to ensure that the anode fits properly within the electrolytic cell.

Surface Preparation

Prepare the titanium surface through methods like mechanical cleaning or acid pickling. This process removes any contaminants and roughens the surface, promoting better adhesion for the coating.

Coating Application

Apply a mixed metal oxide (MMO) coating using thermal spraying or other suitable deposition techniques. The MMO layer typically consists of noble metals such as iridium or ruthenium, enhancing the anode’s efficiency and longevity in chlorine production.

Curing and Heat Treatment

Implement a heat treatment process to cure the coated anodes, which helps in achieving strong bonding between the coating and the titanium substrate. This step also enhances the performance characteristics of the anodes.

Quality Control Checks

Conduct thorough quality control assessments, including dimensional verification and coating thickness measurements. This ensures that the anodes meet specified tolerances and performance standards.

Electrochemical Testing

Perform electrochemical performance evaluations in simulated operational conditions. This testing verifies the anode’s efficiency in chlorine production and assesses its stability over time.

Final Finishing

Complete any necessary finishing operations, such as polishing or additional cleaning, to enhance the surface quality and visual appeal of the anodes.

Packaging and Marking

Package the finished anodes using protective materials to prevent damage during transport. Clearly label the packaging with product specifications, handling instructions, and safety information.

Documentation and Certification

Provide comprehensive product documentation, including technical datasheets, installation instructions, and compliance certifications. This information is crucial for end-users to ensure proper utilization and maintenance of the anodes.

Storage Guidelines

Recommend proper storage conditions, such as a cool, dry environment, to maintain the integrity of the anodes before installation. Advise against exposure to harsh chemicals or corrosive environments.

By following these steps in the production process, manufacturers can ensure that MMO titanium anodes for electrolytic chlorine production equipment are of high quality and perform effectively, contributing to efficient chlorine generation for various applications in water treatment and disinfection.

Quality Inspection

Quality is our top priority. Each anode undergoes stringent testing, including:

- Dimensional Checks: Ensuring specifications meet client requirements.

- Performance Testing: Assessing efficiency under simulated operational conditions.

- Durability Tests: Evaluating corrosion resistance and overall longevity.

Packaging Method

We ensure safe and efficient packaging of our anodes to prevent damage during transport. Our packaging methods include:

- Custom Foam Inserts: To secure the anodes in place.

- Waterproof Materials: Protecting against moisture during shipping.

- Labeling: Clear labels for easy identification and handling.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services, allowing you to customize:

- Design Specifications: Tailor the anodes to your unique requirements.

- Branding Options: Personalize products with your logo and branding materials.

FAQ

Q: What is the typical lifespan of the MMO titanium anodes?

A: Depending on operating conditions, MMO Titanium Anode for Electrolytic Chlorine Production Equipment can last between 5 to 10 years.

Q: Can I customize the dimensions of the anodes?

A: Yes, we provide fully customizable solutions based on your specifications.

Q: Are your products environmentally friendly?

A: Absolutely! Our anodes support sustainable practices in industrial processes.

Contact Us

For more information about our MMO Titanium Anode for Electrolytic Chlorine Production Equipment, or to discuss your specific needs, please contact us at [info@di-nol.com]. Our dedicated team is here to assist you in finding the perfect solution for your electrochemical requirements.

YOU MAY LIKE

VIEW MORELead oxide electrode

VIEW MORELead oxide electrode VIEW MOREelectroplating titanium electrode

VIEW MOREelectroplating titanium electrode VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MOREelectrode anode titanium

VIEW MOREelectrode anode titanium VIEW MOREIr-Ta coated titanium anode

VIEW MOREIr-Ta coated titanium anode VIEW MOREDisc Anode

VIEW MOREDisc Anode VIEW MOREPreparation of MMO titanium anode using chlorate

VIEW MOREPreparation of MMO titanium anode using chlorate VIEW MORETitanium Anode For Metal Electroplating

VIEW MORETitanium Anode For Metal Electroplating