Preparation of MMO titanium anode using chlorate

Uniform current distribution

High electrolysis efficiency

Reduced power consumption

Long service life

- Product Description

Product Introduction

At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we specialize in high-performance Mixed Metal Oxide (MMO) titanium anodes. Our Preparation of MMO Titanium Anode Using Chlorate is a cutting-edge process that ensures the highest quality and efficiency for various applications. These anodes are integral to industries such as electroplating, water treatment, and cathodic protection, providing exceptional durability and performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Substrate Material | Titanium (ASTM Grade 1 or 2) |

| Catalytic Coating | Mixed Metal Oxides (RuO₂, IrO₂, Ta₂O₅) |

| Working Current Density | 200 - 2000 A/m² |

| Operating Life | 3 - 7 years, depending on operating conditions |

| Operating Temperature | Maximum 80°C |

| pH Range Compatibility | Suitable for acidic to neutral (pH 1-9) |

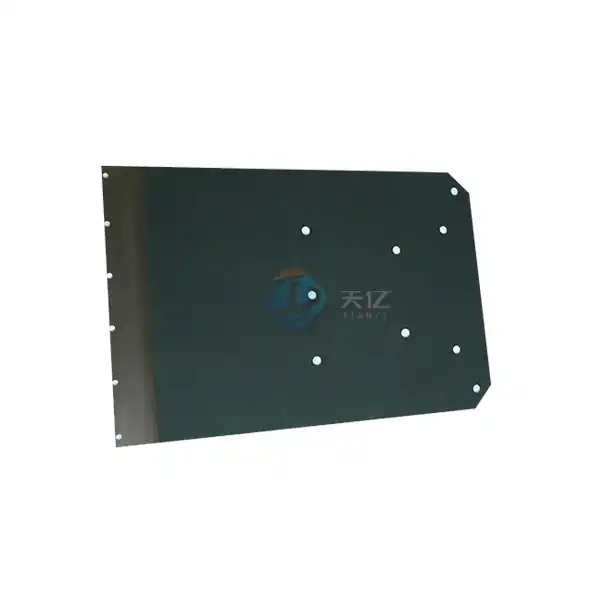

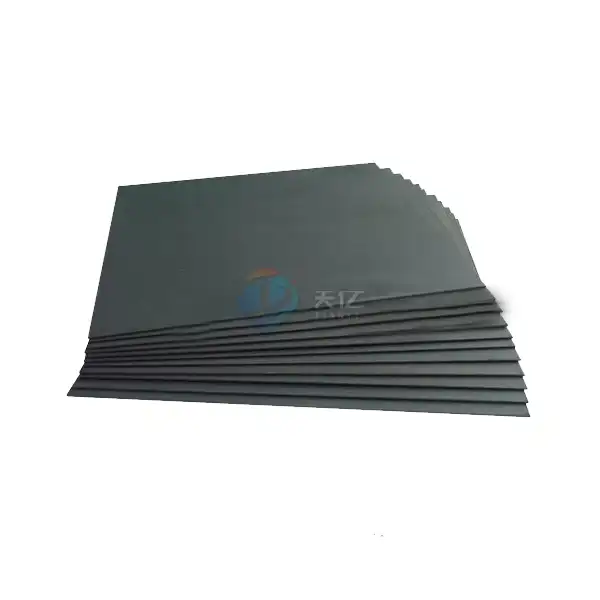

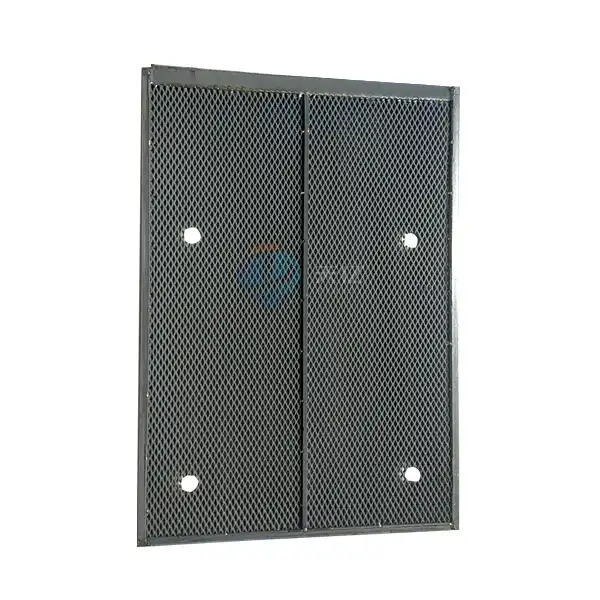

| Available Shapes | Plate, mesh, rod, tubular, custom shapes |

| Coating Thickness | Typically 3 - 15 µm |

| Voltage Range | 4.5 - 5.5 V |

| Primary Applications | Chlorine gas production, wastewater treatment |

| Dimensions | Customizable as per client requirements |

| Certifications | ISO, RoHS |

|  |  |

Product Composition and Design

Preparation of MMO Titanium Anode Using Chlorate utilizes a robust base of high-purity titanium, expertly coated with a mixed metal oxide layer that primarily consists of ruthenium and iridium. This unique composition significantly enhances the anode's electrochemical properties, enabling it to perform exceptionally well in a variety of harsh environments, including high temperatures and aggressive chemical conditions.Our innovative chlorate preparation method plays a crucial role in this process by ensuring a uniform coating that adheres perfectly to the titanium substrate. This uniformity maximizes the surface area of the anode, which is vital for improving its overall performance. Additionally, the enhanced surface area contributes to superior electrical conductivity, leading to more efficient electrochemical reactions. As a result, our Preparation of MMO Titanium Anode Using Chlorate are not only highly effective for chlorine production but also demonstrate longevity and reliability, making them an ideal choice for a wide range of industrial applications.

Product Advantages

- Durability: High corrosion resistance ensures a long service life.

- Efficiency: Optimized electrochemical performance reduces energy consumption.

- Customizability: Tailored dimensions and coatings to meet specific application needs.

- Environmental Compliance: Eco-friendly materials and processes reduce environmental impact.

Technical Features

- High Conductivity: Enhanced performance for electrochemical reactions.

- Low Overpotential: Reduces energy loss during operation.

- Versatile Applications: Suitable for a wide range of industries, including electroplating and water treatment.

Product Application

Our Preparation of MMO Titanium Anode Using Chlorate find applications in:

- Water Treatment: Effective in electrolysis for disinfection and purification.

- Industrial Electroplating: Ensures uniform coating on metal substrates.

- Cathodic Protection: Protects pipelines and structures from corrosion.

- Electrochemical Synthesis: Vital for organic chemical processes.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

Titanium Substrate: Start with high-purity titanium (typically Grade 2 or Grade 5) as the substrate due to its excellent corrosion resistance and mechanical properties.

Metal Oxides: Choose suitable metal oxides, such as iridium, ruthenium, or a combination of both, which are known for their catalytic properties in electrochemical reactions.

Surface Preparation

Cleaning: Remove surface contaminants from the titanium substrate through mechanical cleaning, followed by acid etching (using hydrochloric acid or sulfuric acid) to achieve a roughened surface. This step enhances the adhesion of the MMO coating.

Drying: Thoroughly dry the titanium substrate to prevent moisture interference during the coating process.

Coating Preparation

Chlorate Solution Preparation: Create a solution containing metal chlorates (e.g., iridium chlorate and ruthenium chlorate) mixed in specific ratios. The concentrations should be calculated based on the desired thickness and composition of the MMO coating.

Additives: Incorporate additives to the solution, such as surfactants or stabilizers, to improve coating uniformity and adhesion properties.

Coating Application

Electrodeposition Method: Use an electrodeposition technique, where the titanium substrate is submerged in the chlorate solution and connected to a power supply. Apply a controlled current to facilitate the electrochemical deposition of the mixed metal oxides onto the titanium substrate.

Deposition Parameters: Adjust parameters such as current density, temperature, and deposition time to control the thickness and uniformity of the MMO coating.

Curing Process

Heat Treatment: Once the coating is applied, subject the anode to a heat treatment process. This step involves heating the coated titanium to a specific temperature (e.g., 400-600 °C) for a predetermined duration. This curing process promotes better bonding of the MMO layer and enhances the anode's performance characteristics.

Quality Control

Thickness Measurement: Utilize techniques such as X-ray fluorescence (XRF) or scanning electron microscopy (SEM) to measure the coating thickness and ensure it meets specifications.

Adhesion Testing: Perform adhesion tests to verify the strength of the bond between the titanium substrate and the MMO coating.

Electrochemical Testing

Performance Evaluation: Conduct electrochemical tests in a controlled environment to evaluate the anode's performance, including current efficiency and stability during operation.

Finishing and Packaging

Final Surface Treatment: Optionally polish the surface of the anodes to enhance their appearance and reduce surface roughness.

Packaging: Package the finished anodes in protective materials to prevent damage during transport and storage, and label them with relevant specifications and handling instructions.

By following this process, manufacturers can produce high-quality MMO titanium anodes with optimized performance for various electrochemical applications, including water treatment, electrolysis, and other industrial processes.

Quality Inspection

Our stringent quality control measures include:

- Material Testing: Verification of raw material quality.

- Coating Thickness Measurement: Ensuring uniform application.

- Performance Testing: Assessing electrochemical properties and durability.

Packaging Method

We utilize tailored packaging solutions designed specifically to ensure the safe transport of our products. Each anode is meticulously packaged individually, employing protective materials to prevent damage and preserve quality throughout transit. This attention to detail not only safeguards the integrity of the anodes but also enhances customer satisfaction by ensuring that they arrive in optimal condition. Our commitment to secure packaging reflects our dedication to delivering reliable and high-quality products to our clients.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing clients to specify their unique requirements for anode production, including size, coating, and packaging.

FAQ

Q: What industries use MMO titanium anodes?

A: They are used in water treatment, electroplating, cathodic protection, and more.

Q: How long do MMO titanium anodes last?

A: They typically have a service life of over 10 years with proper usage.

Q: Can you customize the anodes?

A: Yes, we offer tailor-made solutions based on client specifications.

Contact Us

For more information about our Preparation of MMO Titanium Anode Using Chlorate or to discuss your specific needs, please reach out to us at [info@di-nol.com]. We are here to assist you with all your electrochemical material requirements!

_1731380858183.webp)