MMO Titanium Mesh for Corrosion Control

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

MMO Titanium Mesh for Corrosion Control

Product Introduction

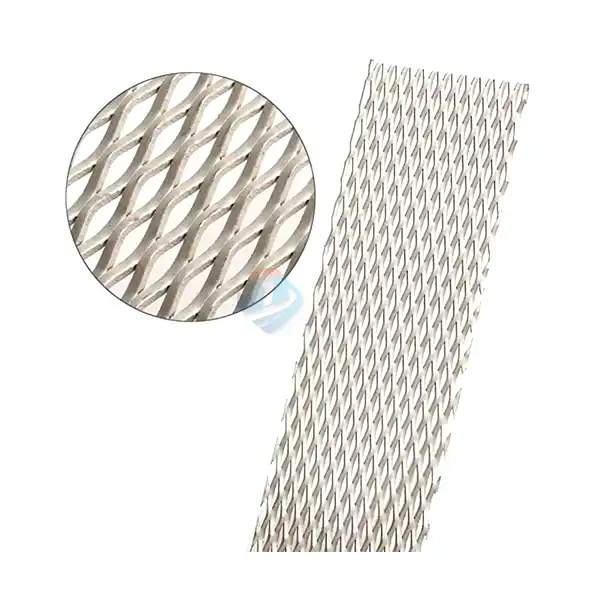

Introducing our MMO Titanium Mesh for Corrosion Control—a cutting-edge solution designed to enhance the longevity and efficiency of various applications, including cathodic protection systems and electrochemical processes. This advanced mesh combines the superior properties of titanium with mixed metal oxide (MMO) coatings, offering exceptional corrosion resistance and durability in harsh environments.

Product Specifications

| MMO titanium mesh belt anode parameters (other specifications can be customized) | |||

| specifications (customizable) | output current | mesh size (mm) | design service life (year) |

| 10mmx76mm | 2.8mA/m2 | 2.5x4.6x0.6 | 20、30、50、70 |

| 13mmx76mm | 3.5A/m2 | 2.5x4.6x0.6 | 20.30、50、70 |

| 19mmx76mm | 5.28A/m2 | 2.5x4.6x0.6 | 20.30,50.70 |

| 1.10mx76mm | 18.8A/m2 | 34x76x0.64 | 20,30,50.70 |

| 1.20mx76mm | 24.4A/m2 | 34x76x0.89 | 20、30、50、70 |

| 1.20mx76mm | 37.8A/m2 | 25x51x0.89 | 20、30、50、70 |

|  |

Product Composition and Design

Our MMO Titanium Mesh is meticulously crafted from high-grade titanium alloy, ensuring a lightweight yet robust structure. The MMO coating is applied uniformly, providing an effective barrier against corrosion and enhancing electrochemical reactions. The mesh design allows for optimal fluid flow and ion exchange, making it ideal for various industrial applications.

Product Advantages

- Corrosion Resistance: The MMO coating significantly enhances the titanium's resistance to corrosion, even in aggressive environments.

- Durability: With a service life of up to 20 years, our titanium mesh outperforms traditional materials.

- Lightweight: Titanium's low density makes it an excellent choice for applications where weight is a concern.

- Customizable Design: We offer tailored solutions to meet specific customer requirements in terms of size and mesh density.

Technical Features

- High Electrochemical Efficiency: The MMO coating optimizes performance in electrochemical reactions, making it suitable for various applications such as cathodic protection and water treatment.

- Temperature Resistance: Our titanium mesh performs reliably under high temperatures, ensuring consistent operation in demanding conditions.

Product Application

MMO Titanium Mesh is versatile and finds application in:

Electroplating

Electrolytic deposition

Water treatment

Desalination

Cathode protection

Chemical production

Wastewater treatment

Metal recovery

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

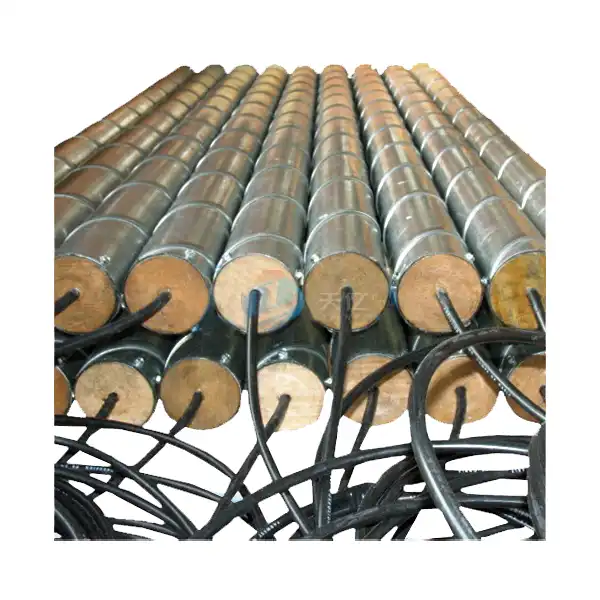

Our Workshop

Product Production Process

Our production process incorporates advanced techniques to ensure the highest quality:

- Raw Material Sourcing: We partner with reputable suppliers to source high-quality titanium.

- Precision Manufacturing: Utilizing state-of-the-art technology, we manufacture the mesh to exact specifications.

- Coating Application: The MMO coating is applied through a meticulous process to ensure uniformity and effectiveness.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each batch of MMO Titanium Mesh undergoes rigorous inspection, including:

- Raw material tests

- Coating thickness measurement

- Corrosion resistance tests to ensure compliance with industry standards.

Packaging Method

We prioritize safe and efficient packaging to prevent damage during transport. Our products are securely packaged using moisture-proof materials, ensuring they arrive in pristine condition.

OEM Service

We offer comprehensive OEM services to cater to the unique needs of our clients. From product design to custom specifications, our team works closely with you to deliver tailored solutions that meet your exact requirements.

FAQ

Q: What is MMO Titanium Mesh used for?

A: It is primarily used in cathodic protection systems and various electrochemical applications to enhance corrosion resistance.

Q: How long does the MMO Titanium Mesh last?

A: With proper installation and maintenance, it can last up to 20 years.

Q: Can I get a custom size?

A: Yes, we offer customizable mesh sizes to suit your specific needs.

Contact Us

For more information about our MMO Titanium Mesh for Corrosion Control, please feel free to reach out. We are here to provide solutions tailored to your needs.

Email: info@di-nol.com

YOU MAY LIKE

_1731641984159.webp) VIEW MOREDiaphragmless electrolyzer

VIEW MOREDiaphragmless electrolyzer VIEW MOREelectrode anode titanium

VIEW MOREelectrode anode titanium VIEW MOREelectrolytic sodium hypochlorite generator

VIEW MOREelectrolytic sodium hypochlorite generator VIEW MORETitanium Anode For Electrolyzed Oxidizing Water

VIEW MORETitanium Anode For Electrolyzed Oxidizing Water_1731642350077.webp) VIEW MORESodium hypochlorite generator

VIEW MORESodium hypochlorite generator VIEW MOREMMO Coated Titanium Mesh Anode

VIEW MOREMMO Coated Titanium Mesh Anode VIEW MOREMMO Titanium Canister Anode

VIEW MOREMMO Titanium Canister Anode VIEW MOREFIP Titanium Anode For Copper Foil Electrolysis

VIEW MOREFIP Titanium Anode For Copper Foil Electrolysis