Power anode rod

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

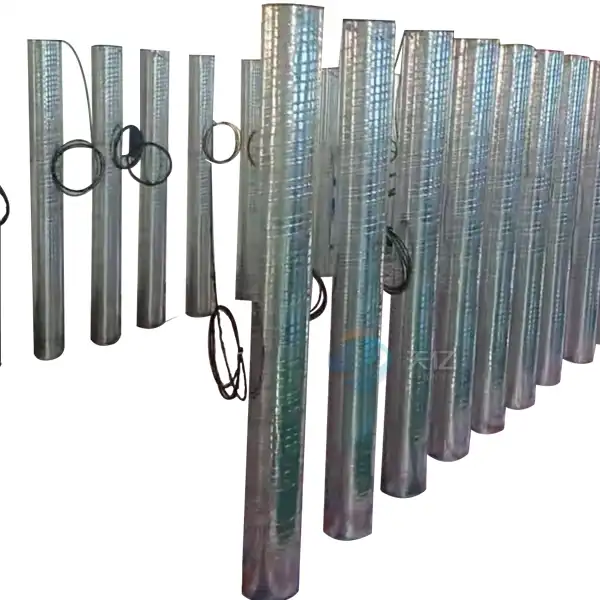

Power Anode Rod Product Introduction

The Power Anode Rod is a crucial component in electrochemical applications, designed to enhance efficiency and performance in various industrial processes. As a leading provider, Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. specializes in manufacturing high-quality MMO (Mixed Metal Oxide) coated titanium anodes, with the product being a prime example of our innovation and commitment to excellence.

Product Specifications

Diameter (mm) | Length (mm) | Current (A/m2) | Life Expectancy |

Φ1.0 | 100-500 | 20—80 | ≥10 Years |

Φ1.5 | 100-500 | 20—80 | ≥10 Years |

Φ2.0 | 100-500 | 20—80 | ≥10 Years |

Φ3.0 | 100-500 | 20—80 | ≥10 Years |

|  |

|  |

Product Composition and Design

The Power Anode Rod is constructed from high-grade titanium, which ensures durability and corrosion resistance. Its unique MMO coating enhances its electrochemical performance, making it suitable for a variety of applications, including industrial electroplating and cathodic protection. The design allows for efficient electron transfer, maximizing output and minimizing energy consumption.

Product Advantages

- Durability: Made from high-strength titanium, ensuring a long lifespan in harsh environments.

- Corrosion Resistance: The MMO coating significantly reduces wear and tear from chemical exposure.

- Customizable Sizes: Available in various lengths and diameters to meet specific project requirements.

- Enhanced Performance: Optimized design for improved electrochemical efficiency.

Technical Features

- High Conductivity: The specialized coating allows for superior electron flow.

- Temperature Stability: Operates effectively in a wide range of temperatures.

- Versatile Applications: Ideal for multiple sectors, including electroplating and water treatment.

Product Applications

The Power Anode Rod is widely used in:

1. Household water heater

2. Commercial water heater

3. Industrial water heater

4. Water tank

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process for the product involves:

Material Selection

High-quality materials such as titanium or corrosion-resistant alloys are selected for the power anode rods. These materials are chosen for their durability and efficiency in conducting electricity, ensuring a long lifespan under operational conditions.

Rod Fabrication

The raw materials are shaped into rods through processes such as extrusion or machining. The rods are produced to specified dimensions, ensuring they meet industry standards for thickness and length, which are crucial for optimal performance.

Surface Preparation

Each rod undergoes surface cleaning and preparation. Techniques such as shot blasting or chemical cleaning are used to remove any contaminants, ensuring a clean surface for optimal coating adhesion.

Coating Application

A protective coating, often composed of mixed metal oxides (MMO), is applied to the surface of the rods. This is typically done through methods like electroplating or spray coating. The coated rods are then cured at controlled temperatures to ensure a strong bond and enhance their electrochemical properties.

Quality Control Testing

Each power anode rod undergoes rigorous quality control assessments. These tests check for uniformity in coating thickness, adherence to dimensions, and electrical conductivity, ensuring that each rod meets the required performance specifications.

Cutting and Customization

The coated rods are cut to custom lengths based on client requirements. This step allows for flexibility in application, accommodating various system designs and installation conditions.

Connection Point Installation

Connection points are installed on the rods to facilitate easy integration into electrical systems. These points are made from corrosion-resistant materials to ensure longevity and reliability in service.

Final Inspection

A thorough final inspection is conducted to confirm that all rods meet the specified standards. This includes visual inspections for defects and testing for electrical performance to ensure they function correctly in their intended applications.

Packaging and Documentation

The finished power anode rods are packaged securely to prevent damage during transit. Each package includes detailed documentation, including installation instructions, maintenance guidelines, and technical specifications to assist users in effectively integrating the rods into their systems.

Quality Inspection

Every Power Anode Rod undergoes rigorous quality inspections, including:

- Raw Material Testing: Ensuring the integrity of materials before production.

- In-Process Inspections: Monitoring at various stages to maintain standards.

- Final Testing: Comprehensive evaluation of performance metrics before packaging.

Packaging Method

We employ safe and efficient packaging methods to protect the product during transit. Custom packaging solutions are designed to minimize damage and ensure secure delivery.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we provide OEM services meticulously tailored to meet the unique needs of our clients. Whether you require specific product specifications, custom branding, or unique design features, our experienced team is dedicated to delivering exceptional solutions. We prioritize understanding your goals and preferences, ensuring that every product aligns with your vision. Our state-of-the-art manufacturing processes and commitment to quality guarantee high-performance products that stand the test of time. With a focus on collaboration and customer satisfaction, we strive to be your trusted partner in bringing your ideas to life.

FAQ

Q: What is the lifespan of a product?

A: The lifespan can vary based on application and environmental conditions but is generally designed for long-term use.

Q: Can I customize the size of the anode rod?

A: Yes, we offer customizable lengths and diameters to suit your project requirements.

Q: How does the MMO coating benefit the anode rod?

A: The MMO coating enhances durability and electrochemical performance, leading to more efficient operations.

Contact Us

For more information or to place an order for the product, please reach out to us at info@di-nol.com. Our dedicated team is ready to assist you with your needs and provide tailored solutions for your business.

_1731642168251.webp)