The Science Behind Diaphragmless Electrolyzers Explained

In the ever-evolving world of electrochemistry, diaphragmless electrolyzers have developed as a groundbreaking innovation, revolutionizing different mechanical forms. These imaginative gadgets have captured the consideration of researchers and businesses alike, much obliged to their special plan and noteworthy capabilities. In this comprehensive direct, we'll dive into the intriguing science behind diaphragmless electrolyzers, investigating their inward workings, applications, and the various preferences they offer over conventional electrolyzer frameworks.

Grasping the Fundamentals of Diaphragmless Electrolyzers

At its center, a diaphragmless electrolyzer is an electrochemical cell planned to conduct electrolysis without the requirement for a physical separator between the anode and cathode compartments. This apparently basic alteration has significant suggestions for the productivity and flexibility of these gadgets.

In conventional electrolyzers, a diaphragm or membrane serves as a boundary between the anode and cathode, avoiding the blending of items created at each cathode. Whereas this partition is significant for numerous applications, it moreover presents certain impediments, such as expanded electrical resistance and potential fouling of the film.

Diaphragmless electrolyzers, on the other hand, rely on careful control of reaction kinetics and mass transport to achieve selective product formation without physical separation. This is accomplished through precise electrode design, optimized electrolyte composition, and fine-tuned operating conditions.

The absence of a diaphragm in these systems offers several advantages:

- Reduced internal resistance, leading to improved energy efficiency

- Simplified cell design and construction

- Enhanced mass transport between electrodes

- Elimination of membrane-related issues such as fouling and degradation

Key Components and Operating Principles of Diaphragmless Electrolyzers

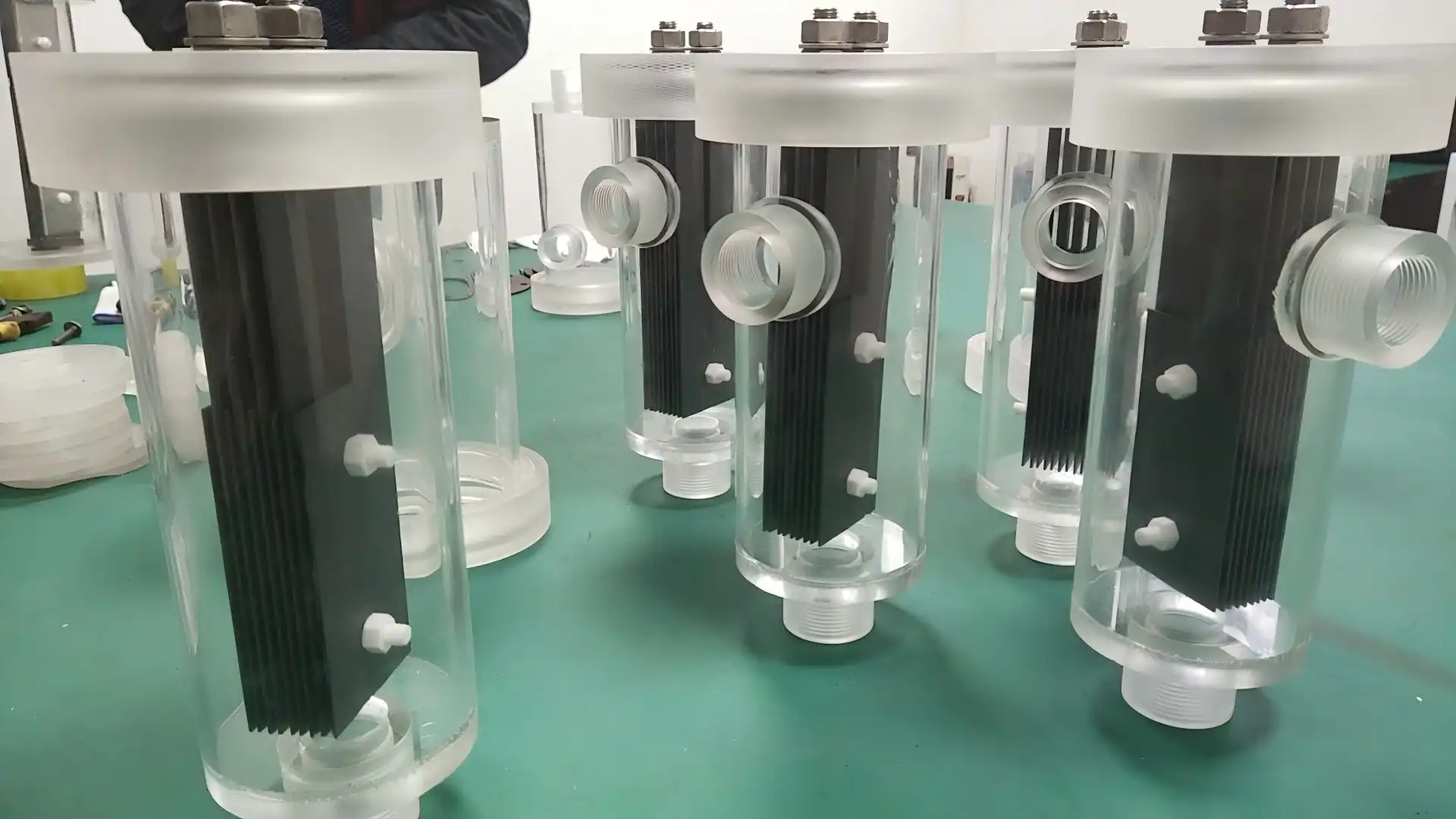

To truly appreciate the ingenuity behind diaphragmless electrolyzers, it's essential to understand their key components and operating principles. While the specific design may vary depending on the application, most diaphragmless electrolyzers share several common elements:

- Electrodes: The heart of any electrolyzer, the electrodes in a diaphragmless system are carefully engineered to promote selective reactions. Advanced materials such as mixed metal oxides (MMO) coated titanium anodes, developed by companies like Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., play a crucial role in ensuring high performance and durability.

- Electrolyte: The composition and properties of the electrolyte are critical in diaphragmless systems. Careful selection of electrolyte components helps control the migration of ions and products within the cell, effectively replacing the role of a physical separator.

- Cell geometry: The spatial arrangement of electrodes and fluid flow patterns within the cell are optimized to minimize unwanted mixing while maximizing desired reactions.

- Power supply and control systems: Precise control of current density, voltage, and other operating parameters is essential for maintaining selective product formation in the absence of a diaphragm.

The operating principle of a diaphragmless electrolyzer relies on creating distinct reaction zones near each electrode. By carefully controlling the local environment around the anode and cathode, it's possible to promote desired reactions while suppressing unwanted side reactions or product mixing. For example, in a diaphragmless chlor-alkali cell, the production of chlorine at the anode and hydrogen at the cathode can be achieved without a separator by maintaining a high pH gradient between the electrodes. This pH gradient acts as a "virtual membrane," preventing the mixing of products.

Applications and Future Prospects of Diaphragmless Electrolyzer Technology

The versatility and efficiency of diaphragmless electrolyzers have led to their adoption in various industries and applications:

- Water Treatment: Diaphragmless electrolyzers excel in generating disinfectants such as sodium hypochlorite on-site, eliminating the need for transportation and storage of hazardous chemicals. The high-efficiency electrolytic sodium hypochlorite generators developed by Shaanxi Tianyi are prime examples of this technology in action.

- Chemical Synthesis: The simplified design of diaphragmless electrolyzers makes them attractive for the production of various chemicals, including hydrogen peroxide, ozone, and organic compounds.

- Metal Processing: In the field of electroplating and metal recovery, diaphragmless systems offer improved mass transport and energy efficiency, leading to higher-quality products and reduced operational costs.

- Energy Storage: As the world shifts towards renewable energy, diaphragmless electrolyzers show promise in hydrogen production for energy storage applications, offering potentially higher efficiencies than traditional electrolysis methods.

Looking to the future, the field of diaphragmless electrolyzer technology is ripe with possibilities. Ongoing research and development efforts are focused on several key areas:

- Advanced electrode materials with improved catalytic properties and longevity

- Novel electrolyte formulations to enhance selectivity and efficiency

- Optimization of cell designs for specific applications and scale-up

- Integration with renewable energy sources for sustainable chemical production

As these advancements continue, we can expect to see diaphragmless electrolyzers playing an increasingly important role in various industries, contributing to more efficient and sustainable processes.

Conclusion

The science behind diaphragmless electrolyzers represents a fascinating intersection of electrochemistry, materials science, and engineering. By eliminating the need for a physical separator between electrodes, these innovative devices offer significant advantages in terms of efficiency, simplicity, and versatility. As research in this field advances, we can expect indeed more energizing advancements and applications for diaphragmless electrolyzer innovation. From progressing water treatment forms to empowering more proficient chemical generation and vitality capacity, these gadgets are balanced to play a pivotal part in forming a more maintainable and mechanically progressed future.

For those interested in learning more about cutting-edge electrochemical technologies, including diaphragmless electrolyzers and advanced electrode materials, Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. stands at the forefront of innovation in this field. To explore how these technologies can benefit your specific applications or to discuss potential collaborations, don't hesitate to reach out to their team of experts at info@di-nol.com.

References

1. Sánchez-Sánchez, C. M., & Bard, A. J. (2009). Electrochemical Processes in Divided and Undivided Cells. Analytical Chemistry, 81(19), 8094-8100.

2. Kato, Z., Bhattarai, J., Kumagai, N., Izumiya, K., & Hashimoto, K. (2011). Durability enhancement and degradation of oxygen evolution anodes in seawater electrolysis for hydrogen production. Applied Surface Science, 257(19), 8230-8236.

3. Gilliam, R. J., Graydon, J. W., Kirk, D. W., & Thorpe, S. J. (2007). A review of specific conductivities of potassium hydroxide solutions for various concentrations and temperatures. International Journal of Hydrogen Energy, 32(3), 359-364.

4. Pletcher, D., & Walsh, F. C. (1990). Industrial electrochemistry (2nd ed.). Springer Science & Business Media.

5. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.