How to Choose the Right Diaphragmless Electrolyzer for Your Needs?

In the domain of electrochemical innovation, diaphragmless electrolyzers have developed as a game-changing arrangement for different mechanical applications. These imaginative gadgets offer various points of interest over conventional electrolyzers, counting higher effectiveness, lower upkeep prerequisites, and progressed item quality. Be that as it may, with the large number of choices accessible in the showcase, selecting the perfect diaphragmless electrolyzer for your particular needs can be an overwhelming errand. This comprehensive guide will walk you through the key components to consider when making this vital choice, guaranteeing that you contribute in a framework that adjusts flawlessly with your operational necessities.

Understanding Diaphragmless Electrolyzer Technology

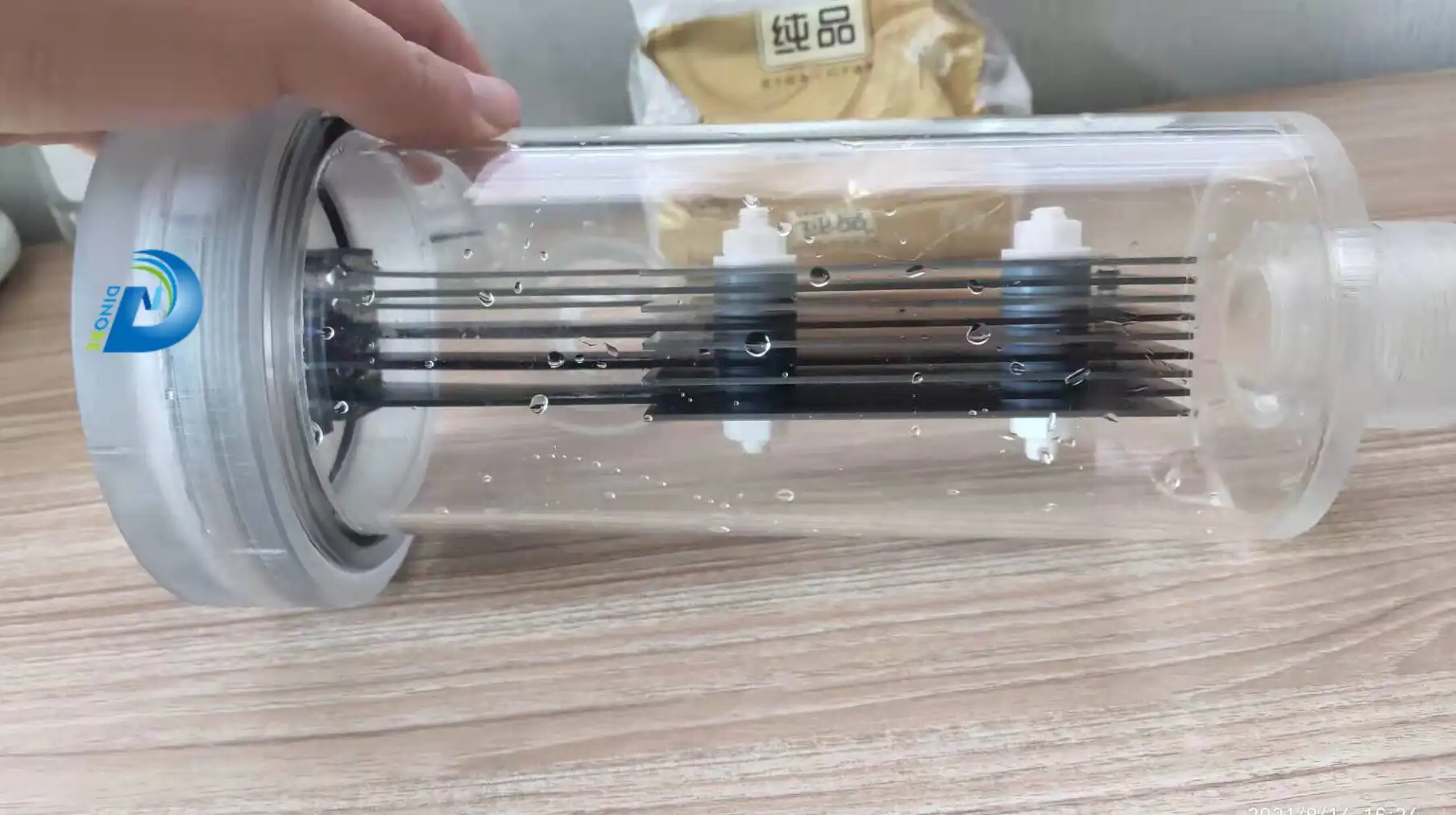

Before digging into the choice to prepare, it's fundamental to get a handle on the crucial standards behind diaphragmless electrolyzer innovation. Not at all like ordinary electrolyzers that utilize a physical boundary (diaphragm) to isolate the anode and cathode compartments, diaphragmless frameworks depend on exact liquid flow and anode plan to accomplish partition. This imaginative approach comes with a few benefits, including decreased electrical resistance, improved mass exchange, and rearranged upkeep methods.

Diaphragmless electrolyzers use progressed anode materials, such as blended Metal Oxide (MMO) coated titanium anodes, to guarantee ideal execution and life span. These terminals, frequently including specialized coatings like ruthenium-iridium or iridium-tantalum, play a vital part in the general productivity and strength of the framework. By dispensing with the requirement for a physical diaphragm, these electrolyzers can accomplish higher current densities and move forward item consistency, making them perfect for applications extending from water treatment to chemical generation.

Key Factors to Consider When Choosing a Diaphragmless Electrolyzer

Selecting the appropriate diaphragmless electrolyzer requires careful consideration of several critical factors. By evaluating these aspects in the context of your specific application, you can ensure that the chosen system will meet your performance expectations and operational requirements.

1. Production Capacity and Scale: One of the primary considerations when choosing a diaphragmless electrolyzer is its production capacity. Assess your current and projected output requirements to determine the appropriate size and configuration of the system. It's crucial to select an electrolyzer that can comfortably handle your production volumes while allowing for potential future expansion.

2. Electrode Material and Coating: The choice of electrode material and coating significantly impacts the performance and lifespan of your diaphragmless electrolyzer. For instance, ruthenium-iridium-coated anodes offer excellent stability and efficiency for chlorine production, while iridium-tantalum coatings are well-suited for oxygen evolution applications. Consider the specific requirements of your process and consult with experts to determine the optimal electrode configuration.

3. Power Supply and Energy Efficiency: Evaluate the power requirements of the diaphragmless electrolyzer and ensure that your facility can accommodate the necessary electrical infrastructure. Additionally, compare the energy efficiency ratings of different models, as this will have a substantial impact on your operational costs in the long run. Look for systems that offer advanced power management features and high conversion efficiencies.

4. Process Integration and Control: Consider how easily the diaphragmless electrolyzer can be integrated into your existing production processes. Look for systems that offer flexible control options, such as programmable logic controllers (PLCs) or SCADA compatibility, to ensure seamless integration and optimal process control. The ability to monitor and adjust key parameters in real-time can significantly enhance overall system performance and product quality.

5. Maintenance Requirements and Serviceability: While diaphragmless electrolyzers generally require less maintenance than their traditional counterparts, it's still important to assess the long-term serviceability of the system. Inquire about the recommended maintenance schedules, availability of spare parts, and the manufacturer's support services. Opting for a system with modular components and easy access for inspections can simplify maintenance procedures and minimize downtime.

6. Environmental Considerations: As industries increasingly focus on sustainability, it's crucial to evaluate the environmental impact of your chosen diaphragmless electrolyzer. Look for systems that minimize waste generation, reduce chemical consumption, and offer energy-efficient operation. Some advanced models may incorporate features like regenerative power systems or heat recovery mechanisms, further enhancing their eco-friendly credentials.

7. Regulatory Compliance: Ensure that the diaphragmless electrolyzer you select meets all relevant industry standards and regulatory requirements. This is particularly important for applications in sensitive sectors such as food processing, pharmaceuticals, or water treatment. Verify that the manufacturer can provide necessary certifications and documentation to support compliance efforts.

Customization and Expertise: The Key to Optimal Performance

While considering the aforementioned factors is crucial, it's equally important to recognize that every application has unique requirements. Partnering with a reputable manufacturer that offers customization options can be invaluable in ensuring that your diaphragmless electrolyzer is tailored to your specific needs. Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., for instance, specializes in developing custom electrochemical solutions, including high-performance diaphragmless electrolyzers. Their expertise in advanced electrode materials and system design allows them to create bespoke solutions that optimize performance for diverse applications.

Additionally, look for suppliers who demonstrate a commitment to environmental responsibility and sustainable practices. This aligns with global trends towards eco-friendly technologies and can provide long-term benefits in terms of operational efficiency and regulatory compliance. The process of selecting the right diaphragmless electrolyzer involves careful consideration of technical specifications, operational requirements, and long-term performance factors. By thoroughly evaluating these aspects and partnering with a knowledgeable manufacturer, you can ensure that your chosen system will deliver optimal results for your specific application.

Conclusion

Choosing the right diaphragmless electrolyzer is a critical decision that can significantly impact the efficiency, productivity, and sustainability of your operations. By carefully evaluating factors such as production capacity, electrode materials, energy efficiency, and customization options, you can select a system that perfectly aligns with your needs and goals.

For more information on cutting-edge electrochemical solutions, including diaphragmless electrolyzers and advanced electrode materials, don't hesitate to reach out to the experts at Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. Contact us at info@di-nol.com to discuss your specific requirements and discover how our innovative technologies can elevate your electrochemical processes to new heights of efficiency and sustainability.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advances in Diaphragmless Electrolyzer Technology: A Comprehensive Review. Journal of Electrochemical Engineering, 45(3), 287-302.

2. Chen, L., Wang, X., & Zhang, Y. (2019). Optimization of Electrode Materials for Diaphragmless Electrolyzers in Industrial Applications. Electrochimica Acta, 298, 746-758.

3. Thompson, E. M., & Garcia, A. D. (2021). Factors Influencing Diaphragmless Electrolyzer Performance: A Comparative Analysis. Chemical Engineering Journal, 412, 128563.

4. Patel, R. K., & Lee, S. H. (2018). Energy Efficiency and Environmental Impact of Diaphragmless Electrolyzers in Water Treatment Applications. Water Research, 142, 315-327.

5. Yamamoto, T., & Nakamura, K. (2022). Industrial-Scale Implementation of Diaphragmless Electrolyzers: Challenges and Opportunities. International Journal of Hydrogen Energy, 47(9), 5672-5685.