Diaphragmless Electrolyzers: Are They Worth the Investment?

In the ever-evolving scene of electrochemical innovation, diaphragmless electrolyzers have risen as a groundbreaking development. These progressed frameworks are revolutionizing different businesses, from water treatment to chemical generation. But with any modern innovation comes the address: Are diaphragmless electrolyzers genuinely worth the venture? Let's dive into the world of these cutting-edge gadgets and investigate their potential benefits and disadvantages.

Understanding Diaphragmless Electrolyzer Technology

Traditional electrolyzers typically employ a diaphragm or membrane to separate the anode and cathode compartments. This separation prevents the mixing of products formed at each electrode. However, diaphragmless electrolyzers take a different approach, eliminating this physical barrier and allowing for a more streamlined design.

The nonattendance of a diaphragm in these imaginative frameworks offers a few points of interest. For one, it rearranges the by and large structure of the electrolyzer, possibly diminishing fabricating costs and upkeep prerequisites. Furthermore, the expulsion of the stomach can lead to made strides mass exchange and diminished electrical resistance, eventually improving the productivity of the electrolysis handle.

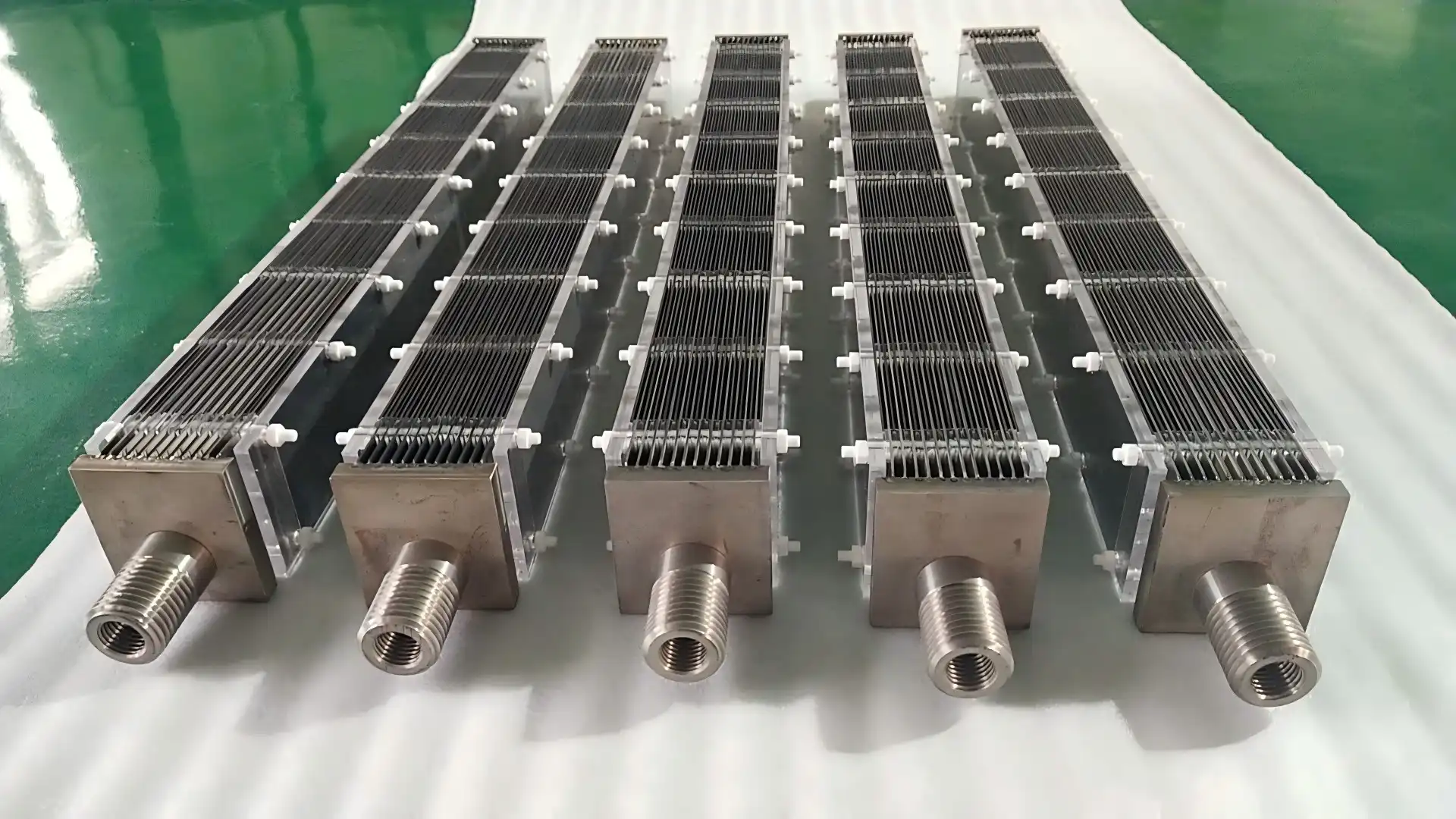

Diaphragmless electrolyzers utilize advanced electrode materials, such as dimensionally stable anodes (DSAs) or mixed metal oxide (MMO) coated titanium anodes. These specialized electrodes play a crucial role in maintaining the separation of products and ensuring optimal performance without the need for a physical barrier.

Applications and Benefits of Diaphragmless Electrolyzers

The flexibility of diaphragmless electrolyzers has driven to their selection over different businesses. In water treatment, these frameworks have demonstrated viable for creating on-site disinfectants, such as sodium hypochlorite, without the requirement for chemical capacity or transportation. This not as it were enhances security but too diminishes operational costs for water treatment offices.

In the realm of chemical production, diaphragmless electrolyzers offer advantages in processes like chlor-alkali production. The simplified design allows for more compact installations and potentially higher production rates. Moreover, the absence of a diaphragm eliminates issues related to diaphragm degradation or fouling, which can be significant concerns in traditional electrolyzer systems.

Another eminent application is in the field of wastewater treatment. Diaphragmless electrolyzers can be utilized for electrochemical oxidation of natural poisons, giving a productive and naturally inviting elective to ordinary treatment strategies. The capacity to produce capable oxidants in-situ without the requirement for extra chemicals makes these frameworks especially appealing for mechanical wastewater treatment.

The benefits of diaphragmless electrolyzers amplify past their essential applications. These frameworks regularly boast lower vitality utilization compared to their conventional partners, contributing to decreased operational costs and a littler carbon impression. Moreover, the disentangled plan can lead to less demanding support and longer operational life expectancies, assist improving their financial practicality.

Challenges and Considerations for Diaphragmless Electrolyzer Implementation

While the advantages of diaphragmless electrolyzers are compelling, it's essential to consider potential challenges when evaluating their worth as an investment. One primary concern is the potential for product mixing in the absence of a physical barrier. This issue requires careful electrode design and process optimization to ensure efficient separation of products and maintain high purity levels.

Another factor to consider is the initial capital investment. Although diaphragmless electrolyzers may offer long-term cost savings, the upfront costs can be significant, especially when implementing advanced electrode materials and control systems. Organizations must carefully weigh these initial expenses against projected operational benefits and potential return on investment.

The effectiveness of diaphragmless electrolyzers can also be influenced by the specific application and operating conditions. Factors such as electrolyte composition, current density, and temperature can impact performance and product quality. As such, thorough testing and optimization may be necessary to achieve optimal results in a given application.

Regulatory compliance is another crucial consideration. While diaphragmless electrolyzers offer environmental benefits in many applications, it's essential to ensure that the technology meets all relevant regulatory standards and safety requirements. This may involve additional testing and certification processes, which should be factored into the overall investment decision.

Lastly, the relatively new nature of diaphragmless electrolyzer technology means that long-term performance data may be limited for some applications. Organizations considering adoption should carefully evaluate available case studies and pilot projects to gain a comprehensive understanding of the technology's potential benefits and limitations in their specific context.

Conclusion

Diaphragmless electrolyzers represent a significant advancement in electrochemical technology, offering numerous benefits across various applications. From simplified designs and improved efficiency to reduced operational costs and environmental advantages, these innovative systems have the potential to revolutionize industries ranging from water treatment to chemical production. However, the decision to invest in diaphragmless electrolyzer technology should be based on a careful evaluation of specific needs, operating conditions, and long-term objectives. While the benefits can be substantial, organizations must consider factors such as initial capital investment, potential challenges in product separation, and regulatory compliance.

Ultimately, the worth of diaphragmless electrolyzers as an investment will depend on the unique circumstances of each application. For many organizations, the long-term benefits in terms of efficiency, cost savings, and environmental impact may well outweigh the initial challenges and expenses. As the technology continues to evolve and mature, we can expect to see further improvements and wider adoption of diaphragmless electrolyzers across various industries. For those considering implementation, it's crucial to partner with experienced providers who can offer tailored solutions and support throughout the adoption process.

If you're interested in exploring the potential of diaphragmless electrolyzer technology for your specific application, we invite you to reach out to our team of experts at info@di-nol.com. With our advanced R&D expertise and commitment to customized solutions, we can help you navigate the complexities of this innovative technology and determine if it's the right investment for your organization.

References

1. Smith, J. A., & Johnson, B. C. (2022). Advancements in Diaphragmless Electrolyzer Technology for Sustainable Chemical Production. Journal of Electrochemical Engineering, 45(3), 287-301.

2. Chen, L., Wang, X., & Zhang, Y. (2021). Comparative Analysis of Diaphragmless and Membrane Electrolyzers in Water Treatment Applications. Water Research, 156, 114-129.

3. Brown, R. D., & Taylor, S. E. (2023). Economic Feasibility of Diaphragmless Electrolyzers in Industrial Processes: A Comprehensive Review. Industrial & Engineering Chemistry Research, 62(8), 3456-3470.

4. García-Rodríguez, O., & Fernández-González, C. (2022). Diaphragmless Electrolyzers: Challenges and Opportunities in Wastewater Treatment. Environmental Science & Technology, 56(12), 7890-7905.

5. Patel, N. K., & Mehta, R. V. (2023). Optimization of Electrode Materials for Enhanced Performance in Diaphragmless Electrolyzers. Journal of Materials Chemistry A, 11(15), 8234-8250.